Welded Large Steel Pipe

| Price: | 4800.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Super duplex stainless such as duplex is a mixed microstructure of austenite and ferrite which has improved strength over ferritic and austenitic .

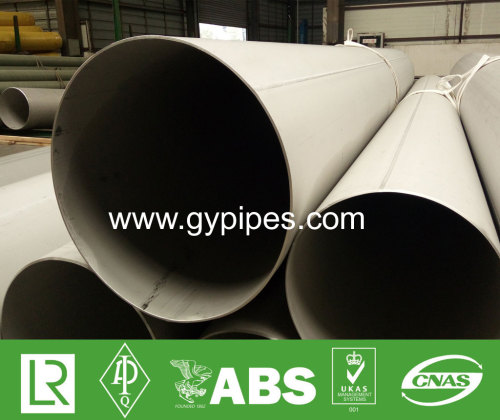

Welded Duplex Large Steel Pipe

Usage: Used for low pressure liquid delivery, such as water, gas, and oil. General, Hydraulic System, Constructural, Decorative/Ornamentalssss

Process:

TIG (DIN 17455; 17457) - tungsten inert gas welding, used for water piping, gas supply pipes and and pipes for the food industry

MIG - metal inert gas welding.

PAW – plasma arc welding.

ERW (Electric Resistance Welded)

HFI (High Frequency Induction)

EFW (Electric Fusion Welded Tube)

LSAW (Longitudinal Submerge-arc Welded) UO(UOE),RB(RBE),JCO(JCOE)

DSAW (Double Submerged arc welded)

SAW (Spiral Welded)

SSAW (Spiral Submerged-arc Welded)

ERW HFI , EFW, LSAW, DSAW:

GB/T3091 Welded steel pipe for low pressure liquid delivery

GB/T9711 Petroleum and natural gas industries--Steel pipe for pipelines

Application of Welded Duplex Large Steel Pipe, standards and regulations:

| Application | GOST | International standard |

| General purpose pipes | GOST 9940-81, GOST 9941-81 | ASTM A312 |

| Heat-exchanger pipes | GOST 9941-81 (gauge pipes) | ASTM A213, DIN 17458-85, ASTM A268. ASTM A269 |

| Instrument piping systems | GOST 19277-73, GOST 10498-82, GOST 14162-79, | DIN 17458-85 |

| Boiler pipes | TS 14-ZR-55-2001, TS 14-3-460-75, TS 14-ZR-197-2001 | |

| Furnace pipes | GOST 9940-81, GOST 9941-81, m/s10H23N18, 15H25T, | ASTM A312, m/s TP310S |

Size:

ERW Electric resistance welding, HFI, EFW:

Outer Diameter: 6mm-610mm (1/16"-24")

Wall Thickness: 0.3mm-22mm

Length: 0.5mtr-20mtr

LSAW, DSAW:

Outer Diameter: 219mm-1820mm

Wall Thickness: 5.0mm-50mm

Length: 6mtr-18mtr

SAW Submerged arc welding, SSAW:

Outer Diamter: 219.1mm - 4064mm (8" - 160")

Wall Thickness: 3.2 mm - 40mm

Length: 6mtr-18mtr

End: square ends (straight cut, saw cut, and torch cut). or beveled for welding, beveled,

Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE)

Packing: Plastic plugs in both ends, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Wrapped in waterproof paper, PVC sleessve, and sackcloth with several steel strips, Plastic caps.

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield

strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

Mill Test Certificate: EN 10204/3.1B

Third party inspection: SGS, BV, Lloyds etc.

Related Search

Find more related products in following catalogs on Hisupplier.com