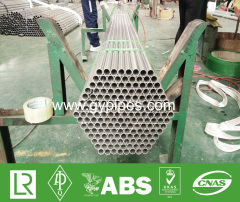

UNS S32750 Welded 7 Inch Stainless Steel Pipe

| Price: | 4800.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Standards:

ASTM/ASME .......... A240 - UNS S32750

EURONORM............ 1.4410 - X2 Cr Ni MoN 25.7.4

AFNOR.................... Z3 CN 25.06 Az

UNS S32750 7 Inch Stainless Steel Pipe

UNS S32750 7 Inch Stainless Steel Pipe is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity, and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion.

Value Added Processes:

Machincut Rings and Discs

up to 124" (3150mm) OD

Drilling, Tapping, & Counterboring, Contour Machincutting, Custom Fabricated Products, Abrasive Waterjet Cutting, Bandsaw Cutting, Laser Cutting, Rolled & Code Welded, Rings or Segments, Polishing

High Definition Plasma Cutting, Plasma Cutting , Flattening Milling, Plasma Beveling, Machine Beveling

General Properties

Alloy 2507 is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion.

The impact strength is also high. Alloy 2507 is not recommended for applications which require long exposures to temperatures above 570°F because of the risk of a reduction in toughness.

UNS S32750 7 Inch Stainless Steel Pipe Applications

Oil and gas industry equipment

Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems

Chemical process industries, heat exchangers, vessels, and piping

Desalination plants, high pressure RO-plant and seawater piping

Mechanical and structural components, high strength, corrosion-resistant parts

Power industry FGD systems, utility and industrial scrubber systems, absorber towers, ducting, and piping

Related Search

Find more related products in following catalogs on Hisupplier.com