|

Ganyeah Holding Group Co., Ltd

|

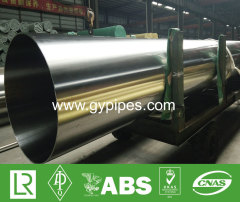

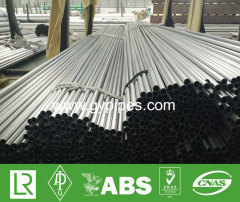

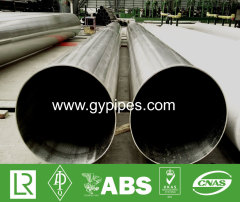

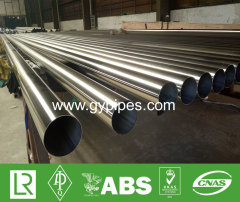

SUS316L Welded 25mm stainless tube

| Price: | 4200.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Mechanical properties:Optimal mechanical and fabrication properties are realised after solution annealing in the temperature range 1075 - 1125°C

SUS316L 25mm stainless tube Description

|

| ||||||||||||||||||||||||

| |||||||||||||||||||||||||

SUS316L 25mm stainless tube Chemical Composition

C | Mn | P | S | Cr | Mo | Si | Ni | N | ||

AISI 316L | Min % | 16,0 | 2,0 | 10,0 | ||||||

Max % | 0,035 | 2,00 | 0,040 | 0,030 | 18,0 | 3,0 | 0,75 | 15,0 | ||

ASTM A249 (AISI 316L) | ||||||||||

1.4435 | Min % | 17,00 | 2,50 | 12,50 | ||||||

Max % | 0,030 | 2,00 | 0,045 | 0,015 | 19,00 | 3,00 | 1,00 | 15,00 | 0,110 | |

(Key to steel 2010) | ||||||||||

S 31603 | Min % | 16,0 | 2,0 | 10,0 | ||||||

Max % | 0,035 | 2,0 | 0,045 | 0,030 | 18,0 | 3,0 | 1,0 | 15,0 | ||

ASTM A 312 (TP 316L) | ||||||||||

SUS316L 25mm stainless tube Physical properties

Property | Value |

Density: lbs /cm3 | 0,29 |

Hardness: HB30 | <=215 |

magnetizable | no |

resistant to intercrystalline corrosion | yes |

Temperature T | Specific heat | Thermal conductivity | Electric resistance | Modulus of elasticity | Expansion rate from 70°F bis T |

20 / 68 | 500 | 14,0 (8) | 0,75 | 200 (29,0) | |

100 /212 | 14,6 (9) | 194 (28,1) | 16,0 (9,2) | ||

200 /392 | 17,0 (10) | 186 (27,9) | 16,5 (9,5) | ||

300 /572 | 18,0 (11) | 179 (25,9) | 17,0 (9,7) | ||

400 /752 | 20,0 (13) | 171 (24,8) | 17,5 (10,0) | ||

500 /932 | 21,0 (13) | 164 (23,8) | 19,0 (10,2) |

Temperature | 0,2% Yield strength in high temperatures | 1,0% Yield strength in high temperatures | Tensile strength |

°C / °F | Rp 0,2 | Rp 1,0 | Rm |

MPa / ksi | MPa / ksi | ||

100/212 | 165 / 23,9 | 200 / 29,0 | |

200/392 | 137 /19,9 | 165 / 23,9 | |

300/572 | 119 / 19,2 | 145 / 21,0 | |

400/752 | 108 / 15,7 | 135 / 19,6 | |

500/932 | 100 / 14,5 | 128 / 18,6 | |

ksi value calculated | |||

Mechanical properties (20°C / 68°F)

1 %Yield strength ksi | 29 |

|

|

0,,2 %Yield strength ksi | 23,9 | ||

Tensile strength (N/mm2) | 510-710 | annealed / quenched |

|

elongation A5 (%) | >40 |

|

|

Temparature information

Solution heat treatment | |

Working temperature | 1886 ºF to 2030 ºF |

Explanation report | air |

Working temperature | 1886 ºF to 2030 ºF |

Explanation report | annealing time: 5min/mm width |

Solution heat treatment | |

Working temperature | 1562 ºF to 2102 ºF |

Explanation report | air |

Standards / information

Standards | Desciption |

ASTM A 182 | Standard Specification for Forged or Rolled Alloy-Steel Pipe Flanges,Forged Fittings and Valves and Parts for High-Temperature Service |

ASTM A 213 | Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler,Superheater,and Heat-Exchanger Tubes |

Process information

Cold forming | cold processes well- heat treatment required under strain in danger of cold cracking |

Welding | |

- Material classification acc. CEN ISO/TR 15608 | 8.1 |

- Type | well weldable |

- Add. material | 1.4430;1.4574; 1.4403 |

Main fields of application

Details of application | slightly magnetizable, increases with cold processing |

Certifications | certified for building pressure containers in accordance to AD-information sheet W2 |

pharmaceutical industry | |

petrochemical industry | Wärmetauscher |

Fertiliser industry | |

cellulose/paper industry | Bleichbehälter |

textile industry | diverse Behälter-und Anlagenteile |

Chemical Industry | Harnstoffherstellung |

Range of products

Product type | Product |

Processing / Construction | from sheets |

Plates / Sheets | plates/sheets |

Fittings | welded elbows |

Flanges / Collars / Flared tube ends | flared tube end |

Bumped boiler ends / caps / round blanks | from sheets |

Pipes / Tubes | welded pipes/tubes |