You are here: home > Thin Wall Stainless Steel Tube > DS/EN 10312:2004 Thin Wall Stainless Steel Tube Welded

DS/EN 10312:2004 Thin Wall Stainless Steel Tube Welded

| Price: | 3800.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

730640

Production Capacity:

2000Ton/Month

Delivery Date:

15days

Grade:

SUS 304/304L/ 316L/347H/S32...

Inspection:

UT, ET, HT, RT

Certification:

API 5LC,DNV•GL, ABS, TUV, L...

Surface:

Pickling,annealing,polishin...

Origin:

China

Means of Transport:

Ocean,Land

Packing:

Plastic, Wooden Case, Other...

Brand:

Ganyeah

Standard:

Astm a312/Astm a778/Astm a5...

Section Shape:

Round

Length:

6 m or as customers' reques...

HS Code:

730640000/730611000

Specifications:

1.EN10312 Thin-wall Stainless Steel Water Pipes

2.Grade:TP304,TP304L,TP316L

3.OD:9.5-1200MM

4.WT:0.5-20MM

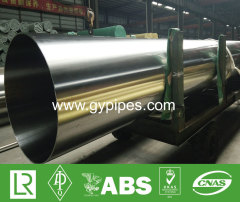

DS/EN 10312:2004 Thin Wall Stainless Steel Tube

Manufacturing Process Overview The manufacturing process utilizes the latest advance Tri-Cathode welding technology incorporating with Japanese designed on-line heat annealing furnace and on-line Eddy Current defect detector. The DS/EN 10312:2004 Thin Wall Stainless Steel Tube are subjected to further 100% Orbital Eddy Current testing back up with hydrostatic testing as standard procedure. |

Quality Control

All our finished products undergo extensive and strict quality tests before being delivered to our customers.

- Elongation Test

- Yield Strength Test

- Hardness Test

- Flattening Test

- Tensile Test

- Hydrostatic Test

Mill certificate which contains the result of the mechanical tests and hydrostatic test will be provided to our customers.

| Typical Applications DS/EN 10312:2004 Thin Wall Stainless Steel Tube are most widely used in industries such as: |

- Water Works & Treatment

- Palm Oil Refinery

- Sugar Refinery

- Biodiesel Plants

- Cement Plants

- Paper & Pulp

- Food Processing

- Petrol-Chemical

- Pharmaceutical

- Air-Conditioning

- Marine Engineering

- Oil & Gas... Etc.

Mechanical Properties

| Standard Specification | Type of Grades Available | Tensile Strength min (N/mm2) | Yield Strength min (N/mm2) | Elongation 2in or 50mm min % |

| ASTM A312 | TP 304 | 515 | 205 | 35 |

| TP 304L | 485 | 170 | 35 | |

| TP 316 | 515 | 205 | 35 | |

| TP 316L | 485 | 170 | 35 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Stainless Welded Steel Tube

Welded Stainless Steel Tube

Stainless Steel Welded Tube

Stainless Steel Thin

Welded Steel Tube

Carbon Welded Steel Tube

More>>

Find more related products in following catalogs on Hisupplier.com