|

Ganyeah Holding Group Co., Ltd

|

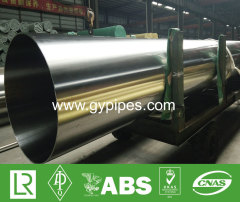

Stainless Steel AISI 304 Tube

| Price: | 3300.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Welded by the Tungsten Inert Gas (TIG) process, no filler rod or any additional metal is used to complete the weld.

Our EN 10312 Stainless Steel AISI 304 Tube manufacturing process begins with cold rolled strip of metal, roll formed into tubular shape and seam welded without the use of any filler material. The as-welded tube is then reduced in size a number of times through various cold working techniques until reaching the exact size, tolerances, and temper our customers require.

After each cold working cycle the tubes are cut, cleaned and heat treated in preparation for the next cold working step. Before reaching final size, our weldrawn products will undergo a minimum of two draw cycles reducing their cross-sectional area by at least 40% after welding.

Our manufacturing process employs a combination of value-added steps to produce the highest quality tubing that meets the exact specifications supplied by our customer. Tubes can be created in a variety of different sizes and shapes from a wide range of alloys. A brief description of the operations we use during production can be found below.

Forming and welding

A precision cold rolled strip, slit to our specified thickness and width, is fed through a series of contoured roll stands. These progressively form the strip into tubular shape. The formed strip is then fed through the weld box, where a single torch fuses the edges together using a Tungsten Inert Gas (TIG) welding process. Fine control over welding parameters - torch settings, gas flow, material speed, etc - enables us to weld a wide range of specialty alloys while ensuring high integrity of the weld zone. After welding, the as-welded tube shells are then cut to specific lengths and weights according to the final tube requirements.

Tube rolling

Like pilgering, tube rolling also uses compression to reduce the size of EN 10312 Stainless Steel AISI 304 Tube. However, while pilgering uses a pair of grooved, tapered dies to work the metal over a tapered mandrel, tube rolling utilizes one or two sets of rolls with constant cross-section grooves on the circumference of the tube. Generally, the process employs a cylindrical mandrel with little or no taper. The rolls are driven by rack and pinion gears of different radii along profiled cams, completing multiple 360º rotations around the tube.

Tube rolling is a very precise method of reducing very thin walled and/or smaller diameter tubes, and is often used as the final cold working step. By rolling, we're able to achieve exceptional control over dimensional tolerances and surface finish while also minimizing material loss and improving the metal's microstructure. Because it uses compression, tube rolling is well suited to processing unique metals like titanium and zirconium alloys.

Our tube rolling capabilities include both classic 3-roll (single roll set) tube rollers and an advanced 6-roll (2 roll sets) approach that Superior Tube developed and patented.