|

Ganyeah Holding Group Co., Ltd

|

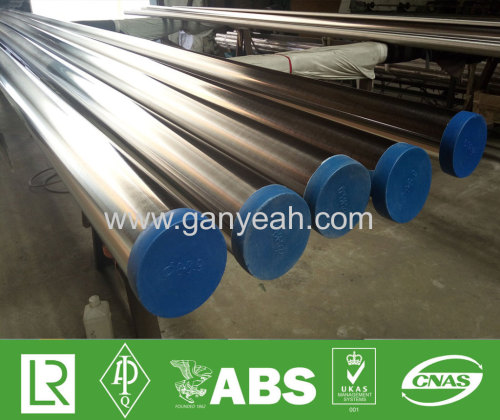

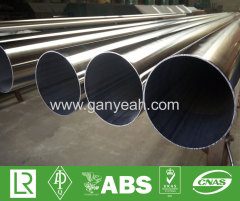

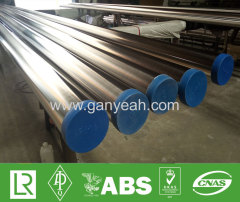

Polished Stainless Tubing Welded

| Price: | 3600.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

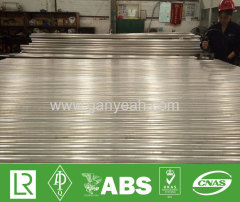

Tube Surface Finish / Polishing:

1.Bright annealed (Mill Finish)

2. Inside bead rolled.

3. Inside polished 240Grit. 320Grit.

Mirror Polished Stainless Tubing Welded ASTM A270 Corrosion Resistant

Quick Detail:

SIZE RANGE :

STEEL TYPES | SIZE RANGE |

Stainless steel welded pipe&tube | OD: 10-304.8mm WT: 0.25-12mm |

MAIN STEEL TYPE AND GRADE :

PRODUCTS | TYPICAL STEEL GRADE |

Austenitic | TP304,TP304L,TP304H,TP316,TP316L,TP316H,TP316Ti TP321,TP321H,TP347H,904L,TP310H,TP310S,TP317,TP317L |

Duplex / Super Duplex | S31803, S32205, S32750 |

Stainless Steel Material Grade:

Austenitic | Equivalent standard | Typical chemical composition | ||||||

ASME | AISI UNS | EN | JIS | C(max) | Cr | Ni | Mo | Cu |

Austenitic Stainless steel tube/Corrosion Resistant | ||||||||

TP304 | S30400 | 1.4301 | SUS 304 | 0.08 | 18.0 | 8.0 | ||

TP 304L | S30403 | 1.4307 | SUS 304L | 0.035 | 18.0 | 8.0 | ||

TP 304H | S30403 | 1.4948 | SUS 304H | 0.04-0.1 | 18.0 | 8.0 | ||

TP 321 | S32100 | 1.4541 | SUS 321 | 0.08 | 17.0 | 9.0 | ||

TP 321H | S32100 | 1.4878 | SUS 321 | 0.04-0.1 | 17.0 | 9.0 | ||

TP 347 | S3470 | 1.455 | SUS 347 | 0.08 | 17.0 | 9.0 | ||

TP 347H | S34709 | SUS 347 | 0.04-0.1 | 17.0 | 9.0 | |||

TP 316 | S31600 | 1.4401 | SUS 316 | 0.06 | 16.0 | 11.0 | ||

TP 316L | S31603 | 1.4404 | SUS 316L | 0.03 | 16.0 | 10.0 | 2.0 | |

TP 316H | S31609 | SUS 316H | 0.04-0.1 | 16.0 | 11.0 | 2.0 | ||

TP 316Ti | S31635 | 1.4571 | SUS 316Ti | 0.03 | 16.0 | 10.0 | 2.0 | |

TP 317 | S31700 | 1.4438 | SUS 317L | 0.08 | 18.0 | 11.0 | 3.0 | |

TP 317L | S31703 | 1.4438 | SUS 317L | 0.03 | 18.0 | 11.0 | 3.0 | |

TP 310 | S31000 | 1.4841 | SUS 310 | 0.08 | 24.0 | 19.0 | ||

TP 310S | S31008 | 1.4845 | SUS 310S | 0.1 | 24.0 | 19.0 | ||

TP 310H | S31009 | 1.4845 | SUS 310H | 0.08 | 24.0 | 19.0 | ||

TP 904L | N08904 | 1.4539 | SUS 904L | 0.02 | 19.0 | 23.0 | 4.0 | 1.0-2.0 |

High Temperature Stainless steel/Heat Resistant Stainless Steel | ||||||||

TP 304H | S30403 | 1.4948 | SUS 304H | 0.04-0.1 | 18.0 | 8.0 | ||

TP 321H | S32100 | 1.4878 | SUS 321 | 0.04-0.1 | 17.0 | 9.0 | ||

TP 347H | S34709 | SUS 347 | 0.04-0.1 | 17 | 9.0 | |||

TP 309S | S30908 | 1.4833 | SUS 310S | 0.08 | 22 | 12.0 | ||

TP 310S | S31008 | 1.4845 | SUS 310S | 0.08 | 24 | 19.0 | ||

TP 310H | S31009 | 1.4845 | SUS 310H | 0.08 | 24 | 19.0 | ||

Duplex Stainless Steel/Austenitic Ferritic Steel | ||||||||

2101 | S32101 | 1.4162 | DP2 | 0.04 | 21 | 1.35 | 0.10 | 0.1 |

2205 | S32205 | 1.4462 | DP2 | 0.03 | 22 | 4.50 | 3.00 | |

S31803 | S31803 | 1.4462 | DP2 | 0.03 | 21 | 4.50 | 2.50 | |

2304 | S32304 | 1.4362 | DP2 | 0.03 | 21.5 | 3.00 | 0.05-0.6 | 0.6 |

2507 | S32750 | 1.441 | DP2 | 0.03 | 24 | 6.00 | 3.00 | 0.5 |

S32760 | 1.4501 | DP2 | 0.03 | 24 | 6.00 | 3.00 | 0.5 | |

Inspection & Test |

1. 100% PMI, Spectro Chemical Analysis Test for Raw Material |

2. 100% Dimension & Visual Examination |

3. Mechanical Properties Test Include Tension Test, Flattening Test,Flange Test, Hardness Test ,Reversed Flattening Test |

4. 100% Hydrostatic Test or 100% NON-DESTRUCTIVE Test (ET or UT) |

5. Radiographic Test for Welded Pipe (shall be accordance with specification,or shall be as agreed upon between the purchaser and vendor) |

6. Straightness Test (optional) |

7. Roughness Test (optional) |

8. Intergranular Corrosion Test(optional) |

9. Impact Test (optional) |

10. Grain Size Determinations (optional) |

NOTES : ALL THE TESTS AND INSPECTION RESULT NEED TO BE SHOWED IN REPORTS ACCORDING TO STANDARD AND SPECIFICATION. |