|

Ganyeah Holding Group Co., Ltd

|

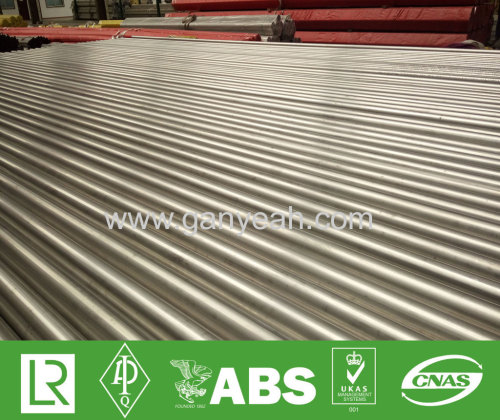

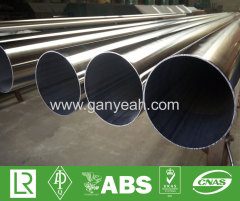

Stainless Steel Round Welded Tubing Sizes

| Price: | 4500.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

When requested we can arrange for shipment and delivery to your dock, or ship your tubes to a third party and if needed can arrange for expedited ship

Stainless Steel Round Tubing Sizes Cold drawing

Typically used for the initial cold work following welding, cold drawing reduces the diameter by pulling the tube through a die that is smaller than the tube. In order to fit the tube into the die, one end is 'swaged' or 'tagged' thereby reducing the diameter of the leading end before drawing. Next, the narrowed end is passed through the die and clamped to a drawing trolley which pulls the tube through the die. After drawing the 'tag' is cropped from the tube end prior to cleaning.

Superior Tube employs three types of cold drawing techniques:

Stainless Steel Round Tubing Sizes Annealing

Annealing is used to soften the metal before further cold working or fabrication processes, and improves the overall metallurgical microstructure of the tube. During tube reduction or cold drawing, it can become hard and somewhat brittle. To be able to draw the tube again, stresses formed during cold working need to be removed to return the material to its normal state.

During annealing the tube is heated to a controlled temperature (up to 2100°F) and soak time. Through this process the tube remains in shape, but the grains in the structure of the tube reform into a regular unstressed pattern. The resulting annealed tube is softer and suitable for redrawing.

Our closely controlled annealing and heat treat processes are audited regularly by our nuclear, medical, and aerospace customers.

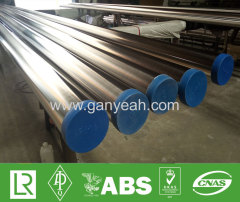

Stainless Steel Round Tubing Sizes Straightening

Drawing and annealing generally results in some degree of bowing, producing a slight bend in the tubing. At Superior Tube we use multiple roll mechanical straighteners in the first stage of finishing. The straightener applies pressure and flex to the product in order to remove bends or bows, resulting in a straightness level of 0.010" per foot, or better. Straightening can introduce slight changes to the size and mechanical properties of the tubing, so these aspects are very carefully controlled during the process.

Stainless Steel Round Tubing Sizes OD belt polishing / grinding (optional)

When specified by our customers, we can polish or grind the outside diameter of their tubes using multiple head belt grinding machines. Polishing is done to improve the cosmetic appearance of the surface, providing a bright, uniform surface finish. Belt grinding is used to remove a small amount of metal from the OD in order to eliminate minor flaws and imperfections, which may result from cold working. Both polishing and grinding reduce the final outside diameter and wall dimensions, so precise controls are used to ensure a uniform size with an extremely high quality surface finish.

Stainless Steel Round Tubing Sizes ID grit blasting (optional)

Grit blasting is used to condition the ID surface, similar to the way grinding conditions the OD surface. An abrasive medium is forced through the tube using compressed air, resulting in a uniform surface finish free of minor cold working flaws. Grit blasting can alter both the ID size and wall thickness, so once again we use precise controls to ensure a uniform size. An extremely high quality finish is achieved. Non destructive testing and inspection

Superior Tube inspects all lots of tubing before shipment to ensure that every aspect of the customer's order has been met. Our in-house inspection capabilities include:

Alloy identity verification (Positive Material Identification, or PMI)

Visual inspection

Dimensional inspection using non-contact techniques such as laser micrometers and air gages whenever possible

Surface roughness testing

Immersion ultrasonic testing to exacting standards

Encircling coil Eddy Current testing

Dye penetrant examination

Hydrostatic pressure testing

Burst pressure testing

Destructive mechanical and metallurgical testing:

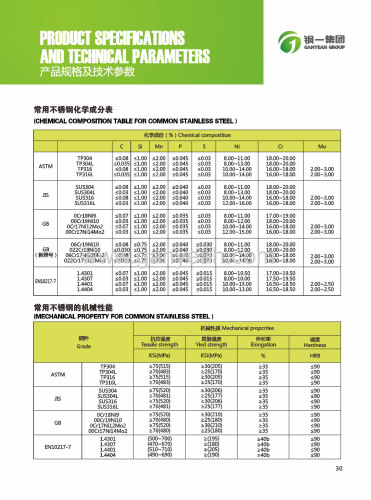

Yield Strength

Ultimate Tensile Strength

Elongation

Rockwell and Knoop Hardness testing

Metallographic analysis for grain size, structure, micro-cleanliness, and flaws

Manipulation testing such as bending, flattening, and flaring

We also work with several qualified independent labs that can perform additional metallurgical testing not listed above, if required by our customers

All shipments include a full Test Certificate showing all required test results and verifying compliance with the order requirements.

Stamping / labeling

All products will be identified in accordance with you requirements. Stamps usually include information such as our lot number, raw material heat number, dimensions, material and other pertinent information. For many products this information is marked in removable ink along the length of the tubing in the lot. For those products that are too small or too thin, the information can be included on material tags or box labels.

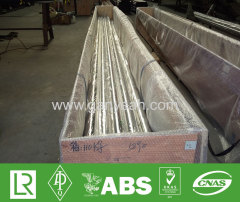

Packaging

Straight lengths of weldrawn tubing can be individually sleeved in paper or plastic and/or packaged in our unique cardboard spacers to ensure no damage occurs during transit. Coiled weldrawn tubes are horizontally packed using paper or cardboard separators to prevent tube-to-tube contact. All tubing is packed in either wooden crates lined with wax craft paper, tri-wall clay-coated reinforced cases, or standard cardboard boxes. Plastic end caps that prevent foreign material from getting inside the tubes are also available upon request.

Shipment

When requested we can arrange for shipment and delivery to your dock, or ship your tubes to a third party and if needed can arrange for expedited shipments. We currently export to over 30 countries all over the world and use Incoterms® as our international framework for shipping.