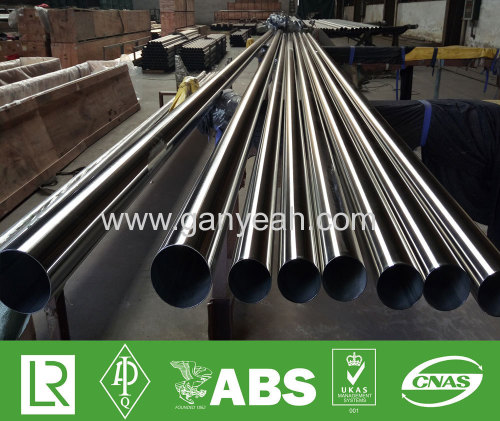

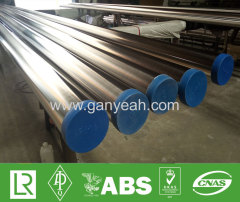

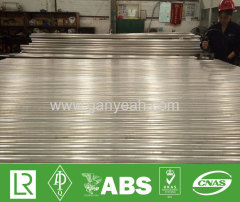

Erw Stainless Steel Pipe

| Price: | 3400.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

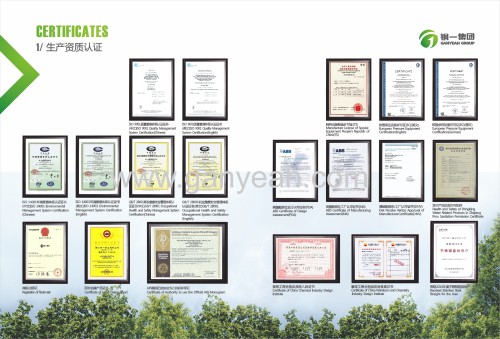

GANYEAH has developed a comprehensive program of quality procedures as well as testing services, many of which are conducted in Metallurgical Test Lab

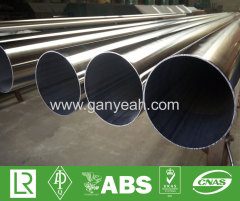

Sanitary Erw Stainless Steel Pipe BRIGHT ANNEALING (Heat Treating)

Temperatures up to 2220° F (1214° C) followed by Rath's rapid quench process ensures proper microstructures and material performance.The reducing atmosphere removes any oxides on the tube.

PASSIVATION

The clean tube is then naturally passivated when exposed to oxygen. A tenacious film of oxide is formed to protect the tubing.

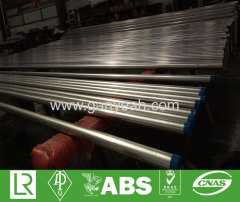

PRECISION SIZING

Ensures uniformity in tubing roundness.• Maintains tolerances better than ASTM specifications

STRAIGHTENING

All tubes are straightened at the mill to tolerances better than the standard commercial tolerance of ±0.030" in 3'.

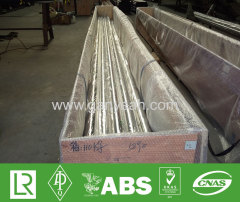

CUTTING AND INSPECTION

Tubing is cut to length at the final stage of mill operations, in lengths up to 80 feet

• Typical stock random mill length: 20' 0" (+1/4"/-0).

• Mill operators also perform final deburring and inspection on every Sanitary Erw Stainless Steel Pipe prior to packing.

STENCILING

Provides material traceability and accountability information for distributors and end users.

EDDY CURRENT TESTING

Performed in accordance with ASTM E426, is done in-line at the tube mill as well as after off-line annealing.

• Checks for any possible defects such as cracks or holes in any portion of the Sanitary Erw Stainless Steel Pipe.

• All Eddy Current Test Operators are ASNT SNT-TC-1A certified.

CLEANING

Removes lubricant residues from sizing and straightening operations.

Related Search

Find more related products in following catalogs on Hisupplier.com