|

Ganyeah Holding Group Co., Ltd

|

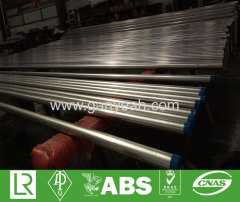

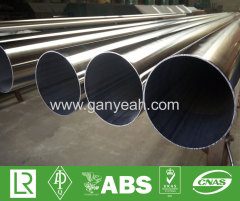

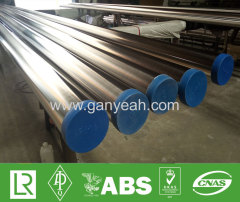

Stainless Steel Pipe Types Mechanically Polished

| Price: | 3300.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

To achieve the desired interior surface finish, an abrasive material, fitted onto a pneumatic polishing head, rotates within the tube for many cycles.

Stainless Steel Pipe Types Mechanically Polished Tubing from GANYEAH may be used in the food, dairy, beverage, pharmaceutical, biopharmaceutical, chemical,petrochemical, power generation, and solar industries.

The mechanical polishing process starts with the simultaneous deburring of both ends of a tube.

To achieve the desired interior surface finish, an abrasive material, fitted onto a pneumatic polishing head, rotates within the tube for many cycles. Any interior residue is removed by blowing a clean wipe through the tube before visual inspection.

The ends of the tube are capped to protect the interior during the OD mechanical polishing process.

Two heads spin the tube before it enters the polisher.GANYEAH employs two multiple-head mechanical polishing centers.

Each OD polishing head uses wet polish, which is composed of lubricant and rough grit that is recirculated and filtered. As the Stainless Steel Pipe Types Mechanically Polished Tubing travels from head to head, the grit gets progressively finer.

Air blows off any residual lubricant as the tube exits the polishing area.

An experienced GANYEAH operator examines the tube's exterior and interior for residuals.

After final visual inspection, both ends are vinyl capped.

The Stainless Steel Pipe Types Mechanically Polished Tubing is line marked with its alloy, size, weld, and manufacturer to ensure complete traceability.

GANYEAH's standard OD mechanical polish finish is a guaranteed maximum 30 μ-in Ra (0.8 μm). For special applications, a maximum

surface roughness of 10 μ-in Ra (0.25 μm) is also available. For protection during shipment, the tube is heat sealed in a poly-sleeve.

Grade | 304 | 304L | 304H | 304N | 304LN | 316 | 316L |

UNS Designation | S30400 | S30403 | S30409 | S30451 | S30453 | S31600 | S31603 |

Carbon (C) Max. | 0.08 | 0.030* | 0.04– 0.10 | 0.08 | 0.030* | 0.08 | 0.030* |

Manganese (Mn) Max. | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 |

Phosphorous (P) Max. | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 |

Sulphur (S) Max. | 0.030 | 0.030 | 0.030 | 0.03 | 0.03 | 0.030 | 0.030 |

Silicon (Si) Max. | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

Chromium (Cr) | 18.0–20.0 | 18.0–20.0 | 18.0–20.0 | 18.0–20.0 | 18.0–20.0 | 16.0–18.0 | 16.0–18.0 |

Nickel (Ni) | 8.0–11.0 | 8.0–12.0 | 8.0–11.0 | 8.0–11.0 | 8.0–11.0 | 10.0–14.0 | 10.0–14.0 |

Molybdenum (Mo) | — | — | — | — | — | 2.00–3.00 | 2.00-3.00 |

Nitrogen (N) | — | — | — | 0.10–0.16 | 0.10–0.15 | — | — |

Iron (Fe) | Bal. | Bal. | Bal. | — | — | Bal. | Bal. |

Other Elements | — | — | — | — | — | — | — |

Physical Properites of Alloys for Welded Tubing

Alloys | UNS Designation | ASTM Specification | Tensile Strength | (min.) | Yield Strength 0.2% Offset (min.) |

MPa | ksi | Mpa | |||

304 | S30400 | A213, A269, A312, A632 | 515 | 75 | 205 |

304L | S30403 | A213, A269, A312, A632 | 485 | 70 | 170 |

304H | S30409 | A213, A269, A312, A632 | 515 | 75 | 205 |

310S | S31000 | A213, A269, A312, A632 | 515 | 75 | 205 |

316 | S31600 | A213, A269, A312, A632 | 515 | 75 | 205 |

316L | S31603 | A213, A269, A312, A632 | 485 | 70 | 170 |

Yield Strength 0.2% Offset (min.) | Elongation in 2" (min.) | Grain Size Requirement | Max. Hardness | Modulus of Elasticity | Mean Coefficient of Thermal Expansion | Thermal Conductivity |

ksi | % | (x106 psi) | (in/in/°Fx10-6) | (BTU-in/ft2-hr-°F) | ||

30 | 35 | - | 92 Rb | 28 | 9.2 | 116 |

25 | 35 | - | 92 Rb | 28 | 9.2 | 116 |

30 | 40 | 7 or coarser | 92 Rb | 28 | 9.2 | 116 |

30 | 40 | - | 90 Rb | 29 | 9.2 | 116 |

30 | 35 | - | 90 Rb | 28 | 9.2 | 116 |

25 | 35 | - | 90 Rb | 28 | 9.2 | 116 |