Stainless Steel Pipe Supports

| Price: | 4800.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Features:

1. Dual Certified Austenitic 316/316L Stainless Steel

2. Annealed Instrumentation Grade Tubing

3. Complies to/Exceeds ASTM A269 Standard

COMPANY PROFILE:

TP316L Stainless Steel Pipe Supports is more than just one of our many products; it is the heart of our business. Since 2010,GANYEAH GROUP has consistently provided quality tubular products and top tier customer service to the industrial marketplace. We service a wide variety of industries including oil and gas, petrochemical, power generation, semiconductor, food and beverage, marine, automotive.

Our technical personnel is strong and the sales team is high-quality. In the global market, Our products have been exported to America, Australia, Singapore,Malaysia, Israel, Canada, South Africa, Italy, South Korea, and other places in the world.

GANYEAH GROUP has advanced, scientific management idea. "Good faith as the foundation, customer foremost" is our consistent business tenet. "Quality first, service foremost" is our principle. "Full varieties" is our market weapon. "The international first-class" is our forever goal.

PRODUCT CATEGORY

Stainless Steel Pipes or Tubes

Stainless Steel Heat Ex-changer U-Tubes

Duplex Stainless Steel Seamless Pipes or Tubes

Stainless Steel Welding Pipes or Tubes

PRODUCT RANGE

S.S. SEAMLESS TUBES

Outer Diameter: 10.29mm to 168.3mm

Thickness:0.9 to 10.0mm

Specification:ASTM/ASME A/SA269/213/789

S.S. WELDED PIPES

Outer Diameter:1/8" to 24"(10.29mm to 609.60mm)

Thickness:1.24mm to 59.54mm

S.S. WELDED PIPES or TUBES

Outer Diameter:6.00mm to 630mm

Thickness:0.5mm to 20mm

LENGTHS

Random Length/Fixed Length

The Maximum Length:22m

CONDITION OF DELIVERY

Annealed and pickle, Polished, Bright Heat Treatment

DESCRIPTION:

| Grade | Austenitic Stainless Steel: TP304,TP304L,TP304/304L,TP304H,TP321,TP321H,TP321/321H,TP316L,TP316/316L,TP316H, TP316TI,TP317L,TP310S,TP347/347H,904Letc. Duplex Steel:S32205,S31803,S32750,S31500 etc. Nickel Alloy:200/201/400/600/601/625/690/800/800HT etc. EN:1.4301,1.4307,1.4306,1.4401,1.4404,1.4335,1.4571,1.4436,1.4438,1.4541,1.4550,1.4435, 1.4580 etc. GOST:03Х18Н1112Х18Н10Т 10Х17Н13М2Т,08Х17Н13М2Т,08Х17Н13М2Т, 12Х18Н9,08Х18Н10 etc. JIS:SUS304TB,SUS304LTB,SUS304HTB,SUS316TB,SUS316LTB,SUS316HTB,SUS317LTB, SUS321TB,SUS321HTB,SUS347TB,SUS347HTB,SUS316TiTB,SUS310STB,SUS310TB etc. GB:06Cr19Ni10,022Cr19Ni10,06Cr17Ni12Mo2,07Cr19Ni10,022Cr17Ni12Mo2,07Cr17Ni12Mo2, 06Cr17Ni12Mo2Ti,06Cr19Ni13Mo3,022Cr19Ni13Mo3,06Cr18Ni11Ti,06Cr18Ni11Nb, 07Cr19Ni11Ti,07Cr18Ni11Nb,20Cr25Ni20,06Cr25Ni20,06Cr19Ni10N,022Cr19Ni10N, 06Cr17Ni12Mo2N, 022Cr17Ni12Mo2N,12Cr18Ni9,16Cr23Ni13,06Cr23Ni13, 022Cr19Ni5Mo3Si2N,022Cr22Ni5Mo3N,022Cr23Ni5Mo3N,022Cr25Ni7Mo4N etc. |

| Spec | ASTM/ASME:A/SA312/511/790/376/269/213/789/A249/A688 DIN:17456,17458,17455 JIS:G3459,G3463 EN:10216-5,10217 GB:GB/T14976,GB/T21833,GB/T14975,GB13296,GB5310,GB9948,GB12771,GB12770 GOST:9941 |

| Testing | Hydraulic Test(A999), Ultrasonic Test(E213), Eddy Current Test(E426), Flatting test(A1016), Impact Test(A370), Intergranular Corrosion Test(A262 E), Flaring Test(A999), Grain Size Test(E112), Inclusions Test(E45),Roughness(ISO 4287), Clean liness(A380), Carbide Precipitation Check(A262 A),Radiation Test(IAEA), Delta Ferrite Content(E562), Pitting Corrsion Test(A923 C) etc. |

| Application | Pipeline Transport, Medical Equipment, Heat Ex-changer, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Food/Beverage/Dairy Products, Machinery Industry, Chemical Industry, Mining, Construction & Decoration. |

| Size | OD:6.00MM-630.00MM), WT:0.5MM ~ 20MM |

| Lenght | 6m or According to Customer′s Request(The Maximum Length:22m) |

| Technique | Cold Rolled, Cold Drawn |

| Surface Treatment | Annealed and Pickled,Mechanical Polish (Up to 800#), Bright Annealed or Polish |

| Delivery Date | 20 Working Days or Customized |

| Market | America, Australia, Singapore,Malaysia, Israel, Canada, South Africa, Italy, South Korea, and other places in the world. |

| Sample | Free Samples But Freight Charge Paid by Customer |

TP316L Stainless Steel Pipe Supports Chemical Composition:

| Chemical Composition | 304/304L(A312) | 316/316L(A312) | 321 (A312) | 304 (A312) | 316L (A312) | 347 (A312) | S32205 (A790) | S31803 (A790) | TP310S (A312) |

| C | ≤0.035 | ≤0.035 | ≤0.08 | ≤0.08 | ≤0.035 | ≤0.08 | ≤0.03 | ≤0.03 | ≤0.08 |

| S | ≤0.030 | ≤0.030 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.02 | ≤0.02 | ≤0.03 |

| P | ≤0.045 | ≤0.045 | ≤0.045 | ≤0.045 | ≤0.045 | ≤0.045 | ≤0.03 | ≤0.03 | ≤0.045 |

| Mn | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 |

| Si | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 | ≤1.0 |

| Cr | 18.0-20.0 | 16.0-18.0 | 17.0-19.0 | 18.0-20.0 | 16-18 | 17.0-19.0 | 22.0-23.0 | 21.0-23.0 | 24.0-26.0 |

| Ni | 8.0-11.0 | 11.0-14.0 | 9.0-12.0 | 8.0-13.0 | 10.0-14.0 | 9.0-13.0 | 4.5-6.5 | 4.5-6.5 | 19.0-22.0 |

| Mo | / | 2.0-3.0 | / | / | / | / | 3.0-3.5 | 2.5-3.5 | ≤0.75 |

| Ti | / | / | 5(C+N)-0.7 | / | / | / | / | / | / |

| N | / | / | 0.1 | / | / | / | 0.14-0.20 | 0.08-0.20 | / |

| Nb | / | / | / | / | / | 10C-1.0 | / | / | / |

Process Flow:

MAIN FACILITLES:

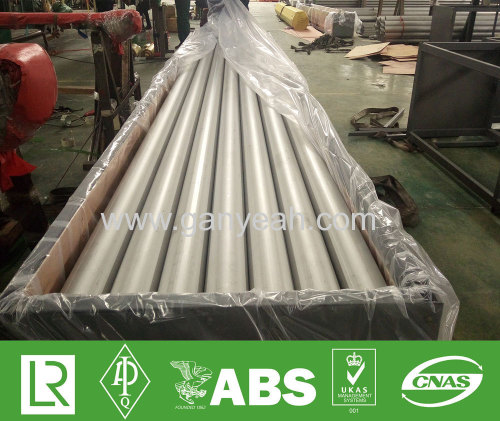

PACKING:

Packaging is one of the best service of our company, in order to prevent the damage from transit, our finished products are packaged carefully.

| Inner Packing | Plastic Bag(every pipe/ tube is sleeved in plastic bag individually), |

| Outer Packing | 1)Woven Packing (standard woven packed for each bundle, around 50-500kgs per bundle 2)As Customers' Request) |

| Iron Box ( strong iron box ,each box can load about 1000kg) | |

| Plywood Case |

WHY CHOOSE GANYEAH GROUP?

1. High quality polish, especially mirror finish with adorable price.

2. High Class technology factory with strict quality control management.

3. Introduced the most advanced pipe-making from Taiwan.

4. Export percentage: 100%

5. Excellent pre-sales,sales,after-sales service.

6. Endeavour to develop new products accorrding to your requirement.

7. Strategic cooperation and finance support to VIP customers

Related Search

Find more related products in following catalogs on Hisupplier.com