You are here: home > Stainless Steel Mechanical Tubing > Stainless Steel Mechanical Welded Tubing Bulk Order

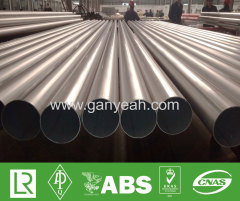

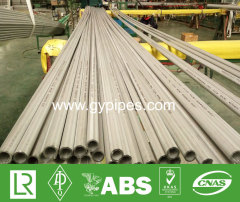

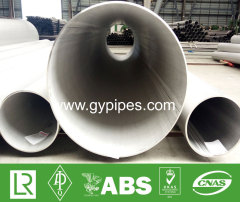

Stainless Steel Mechanical Welded Tubing Bulk Order

| Price: | 3600.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

730640

Production Capacity:

2000Ton/Month

Delivery Date:

15days

Grade:

SUS 304/304L/ 316L/347H/S32...

Inspection:

UT, ET, HT, RT

Certification:

API 5LC,DNV•GL, ABS, TUV, L...

Surface:

Pickling,annealing,polishin...

Origin:

China

Means of Transport:

Ocean,Land

Packing:

Plastic, Wooden Case, Other...

Brand:

Ganyeah

Standard:

Astm a312/Astm a778/Astm a5...

Section Shape:

Round

Length:

6 m or as customers' reques...

HS Code:

730640000/730611000

1/2" to 5" Diameter.

0.049"-0.250" Wall thickness

180,240,320,400,600, and (Polish and Buff)

All Material Produced to ASTM A-554 Specification

Stainless Steel Mechanical Tubing Bulk Order

| Principal Design Features | One of the most widely used and oldest of the stainless steels. This was originally called 18-8 which stood for its chromium and nickel content. It possesses an excellent combination of strength, corrosion resistance and fabricability. It is available in the widest variety of forms and sizes of any stainless steel. | |

| Applications | The list is endless. Almost every conceivable industry uses some of this material in some way. Everything from stovetops to ball point pen barrels to flatware to fasteners has been fabricated from this alloy. | |

| Machinability | Slow speeds and heavy feeds will minimize this alloys tendency to work harden. Due to long stringy chips, the use of chip breakers is advisable. Many companies now offer premium machinability grades, such as CarTech with their Project 70 and 7000 series. | |

| Welding | All fusion and resistance processes have been successfully employed in welding 304. AWS E/ER308 or 312 filler metal is recommended. For cleaner, stronger welds, may users choose 304L which has a controlled low carbon content designed to reduce carbide precipitation at the weld boundaries. | |

| Hot Working | Forging, heading and other hot working should follow uniform heating to 2100-2300 F (1149-1260 C). Rapid cooling is necessary to attain maximum corrosion resistance in finished parts. | |

| Cold Working | Readily fabricated by most cold working methods, 304 may require intermediate annealing to avoid cracking or tearing from radical deformation. Full annealing should follow any operation to reduce internal stress and optimize corrosion resistance. | |

| Annealing | 1850-2050 F (1010-1121 C) followed by rapid cooling. | |

| Hardening | This alloy does not respond to heat treatment. Cold work will cause an increase in both hardness and strength. | |

Stainless Steel Mechanical Tubing Bulk Order

| Density (lb / cu. in.) | 0.285 |

| Specific Gravity | 7.9 |

| Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) | 0.12 |

| Electrical Resistivity (microhm-cm (at 68 Deg F)) | 432 |

| Melting Point (Deg F) | 2650 |

| Modulus of Elasticity Tension | 28 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Stainless Steel Welded Tubing

Mechanical Steel Tubing

Steel Welded Tubing

316l Stainless Steel Tubing

Seamless Stainless Steel Tubing

Mechanical Tubing

More>>

Find more related products in following catalogs on Hisupplier.com