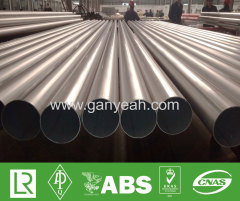

Heat Exchanger 304H Stainless Steel Welded Tube

| Price: | 3400.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

GANYEAH is also having the facility to supply tubes with lower residual stress values, which plays an important role in service life of Heat Exchange

Heat Exchanger 304H Stainless Steel Pipe

GANYEAH is having dedicated facility for manufacturing Heat Exchanger 304H Stainless Steel Pipe using TIG and LASER Welding.

The manufacturing facility is equipped with the state of art Coil Slitting Line, which plays an important role for manufacturing welded tubes. GANYEAH is having the latest generation Tube Mills using On-Line Bright Annealing, On-Line Eddy Current Testing, Two Axis Dimension check including ovality resulting into closer dimensional control.

GANYEAH is also having facility of High Speed Draw Benches for manufacturing Welded and Cold Drawn Tubes in Austenitic and Duplex Stainless Steels in longer length, Off-Line Bright Annealing , Off-Line Eddy Current Testing,Off-Line Ultrasonic Testing etc.

GANYEAH is also having the facility to supply tubes with lower residual stress values, which plays an important role in service life of Heat Exchanger 304H Stainless Steel Pipe.

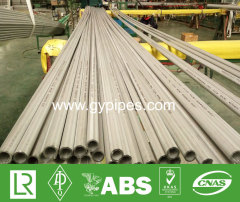

GANYEAH manufactures Austenitic, Super Austenitic , Ferritic , Super Ferritic, Lean Duplex, Duplex and Super Duplex Heat Exchanger 304H Stainless Steel Pipe.

Common Features :

Good Surface Finish

Good Corrosion Resistance

In-house "U" bending facility and "U" bend stress relieving

Ability to produce tubes with stringent NDT requirements of the Client

Ability to handle various Grades of Stainless Steel

Stabilization Heat Treatment facility for Stabilized Stainless Steel Grades

- Power Plants

Stainless Steel Welded Condenser Tubes

Capabilities to manufacture tubes having wall thickness from 0.40 mm to 2.00 mm.

Straight Length upto 25 meters

Stainless Steel Seamless LP and HP Heater Tubes

Capabilities to supply tubes with Very Low Residual Stress Values leading to longer service life

Capabilities to manufacture tubes having wall thickness from 0.40 mm to 2.00 mm

Closer dimensional tolerances

Dedicated facility for manufacturing Tubes in U bend Solution Annealed condition upto developed length of 36 meters

Capabilities to supply Ferritic Stainless Steel tubes for Nuclear Power Plant

Stainless Steel Welded HP Heater Tubes

Capabilities to supply tubes with Very Low Residual Stress Values leading to longer service life

Fully recrystallized microstructure in weld, improving corrosion resistance of Heater Tubes

Closer dimensional tolerances due to Cold drawn tube

Dedicated facility for manufacturing Tubes in U bend Solution Annealed condition upto developed length of 36 meters

Capabilities to supply Ferritic Stainless Steel tubes for Nuclear Power Plant

Capability to supply tubes with Special Chemistry

- General Industries

Manufacturing capabilities to supply Ferritic Stainless Steel tubes for Desalination Plant

Manufacturing capabilities to supply Duplex Welded and Cold Drawn Tubes for Oil and Gas Sector

Manufacturing capabilities to supply Lean Duplex tubes for Process Industries

- SIZE / RANGETHICKNESSSPECIFICATION

Salient Features :

MANUFACTURING RANGE:

| 10.00 MM to 76.00 MM OD | 0.50 MM to 4.00 MM | ASTM A-249, A-268, A-269, A-270, A-554, A-688, A-789, A-803 EN-10217-7 U-Tubes as per Customer's Drawing. | |||

| |||||

| * Sizes and Specifications other than above can be manufactured on request | |||||

Related Search

Find more related products in following catalogs on Hisupplier.com