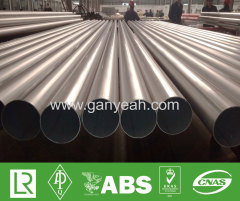

304 Tubing Welded Stainless Steel Mechanical

| Price: | 3600.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

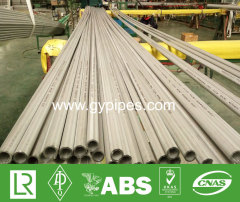

1/2" to 5" RD(22 ga. to 11 ga.)

3/4" SQ to 4" SQ(22 ga. to 11 ga.)

Rect. sizes up to 3" x 4"(20 ga. to 11 ga.)

Some elliptical, oval and sink-drawn

304 Tubing Stainless Steel Mechanical

History Of Stainless Steel

Sheffield, England born Harry Brearly discovered stainless steel in 1913. In an experiment, he found that steel's corrosion resistance increased when the chromium content is raised to 12 percent or more. He is seen as the person who laid the foundation for the development of various stainless steel grades. The development of stainless steel almost came to a complete standstill during the First World War. By the late 1920's it was found that two grades of stainless steel namely martensitic stainless steel and austenitic stainless steel were the most versatile and useful. Martensic stainless steel has a chromium content of between 13 and 18 percent while austenitic stainless steel contains 18 percent chromium and 8 percent nickel. In today's terms stainless steel is used as a generic term to describe corrosion resistant steel that has a minimum chromium capacity of 10.5 percent. The chromium creates a passive and self renewing chromium oxide film around the steel at atomic level and this prevents the iron from rusting.

Stainless Steel Categories?304 Tubing Stainless Steel Mechanical

Stainless steel is divided into 5 main categories. These are Austenitic, martensitic, ferritic, duplex and precipitation hardening.

300 Series Austenitic – Alloys: 301, 302, 303, 304, 305, 308, 309, 310, 314, 316, 317, 321, 330, 347, 384 is chromium-nickel alloy and its strength is developed by cold working. The series is non-magnetic, not heat treatable and has good formability. By adding molybdenum, the corrosion resistance is increased. 304 Tubing Stainless Steel Mechanical is used in food equipment, chemical equipment and architectural applications.

400 Series Ferritic – Alloys: 405, 409, 429, 430, 434, 436, 442, 446 is straight chromium alloy, magnetic but it is not heat treatable. This series is mainly used for automotive trim and cooking utensils.

400 Series Martensitic – Alloys: 403, 410, 414, 416, 420, 422, 431, 440 is straight chromium alloy, magnetic and can be hardened by heat treatment. It is used for fasteners, pump shafts and turbine blades.

Precipitation Hardening – Alloys: 13-8, 15-5, 15-7, 17-4, 17-7 is chromium-nickel, martensitic or austenitic. Develop strength by precipitation hardening reaction due to heat treatment. It is mainly used for valves, gears and petro-chemical equipment.

Duplex – Alloys: 329, 2205, 2304, 2507, 3RE60 is chromium-nickel-molybdenum. This series is more resistant to stress corrosion cracking than austenitic and it is also tougher than fully ferritic alloys. It is mainly used in pipelines or pressure shafting.

Related Search

Find more related products in following catalogs on Hisupplier.com