100% Hydrostatic Test Mechanical Tubing

| Price: | 3600.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

100% Hydrostatic Test and 100% Eddy Current Test

Ultrasonic Test subject to the MPS (Material Purchase Specification)

Ultrasoic measuring of WT

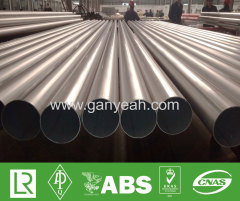

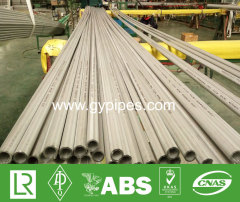

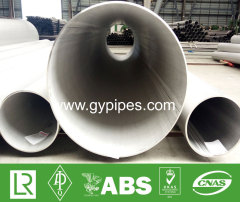

100% Hydrostatic Test Stainless Steel Mechanical Tubing

100% Hydrostatic Test Stainless Steel Mechanical Tubing are divided mostly into square , rectangular and round types with different finishing. Stainless Steel Round Welded Tube: 180 grit, 320 grit, 400 grit, 600 grit & Mill finish Stainless Steel Square Welded Tube: 180 grit , 400 grit , 600 grit & Mill finish Stainless Steel type:304,316 Int›l standard: ASTM A554, JIS G3446, CNS5802

100% Hydrostatic Test Stainless Steel Mechanical Tubing for Mechanical and Structural Purposes ASTM A554, JIS G3446, CNS 5802

FEATURES STANDARD(GRADE): ASTM A554(MT304/304L, MT316/316L) JIS G3446(SUS304TK, SUS316TK) CNS 5802(304TK, 316TK)

O.D.:9.5mm~139.7mm W.T.:0.6~3.05mm WELDING METHOD:TIG or TIG + Plasma or Laser APPLICATION:Construction for building, ornamental tubing etc.

100% Hydrostatic Test Stainless Steel Mechanical Tubing Integrity Tests

Reverse Bend Test :

Flatten to 2 times material thickness.

Flare / Cone Test :

Minimum 1.21 tube diameter (60 deg included angle).

Flange Test :

Minimum 1.10-1.15 tube diameter.

Eddy Current Test :

All tube diameters are on-line eddy-current tested.

Tube Dimensional Tolerances

Outside diameter (OD)

| O/D ≤ 31.8 µm | ± 0.13 µm |

| 31.8 < O/D ≤ 76.2 µm | ± 0.25 µm |

| 101.6 < O/D ≤ 127.0µm | ± 0.38 µm |

| 152.4 < O/D ≤ 203.2µm | ± 0.76 µm |

Ovality :

Difference between maximum and minimum diameters at any one cross section to be within max & min sizes as above.

Thickness tolerance :

to ±0.10mm (AS 1528:1)

Weld Bead :

Weld bead of tube without cold work controlled to 110% of wall thickness

Straightness :

Maximum of 1.0 mm / metre

Length tolerance :

Standard length 6 metres -0 /+35 mm Cut to exact length jobs, by agreement (+/- 1 mm)

Finish

End finish :

Sizes to 203.2 deburred both ends

Finish internal :

Tubes with diameter greater than or equal to 31.8 mm are internally cold worked (Internal weld beaded to tube surface). Tubes with diameter less than 31.8 mm are in as welded condition and internal weld height is controlled to a minimum height.

Finish external :

Available as follows:

As welded condition (external weld bead removed).

May have forming, straightening & weld polish cross hatch marking.Standard Polished equivalent to 320 Grit - typical Ra = 0.5µm to 0.8 µm

Minor form marks may be visible. .

Documentation & Packaging

Packaging :

Polished Tube is individually plastic sleeved in a bundle with steel strapped cleats and plywood for forklift plate.

Traceability :

Controlled batch traceability from raw material to finished tube. For traceability purpose the tube is either inkjet marked or attached with label identifying sizes , batch & trace numbers.

Test certificate :

Raw material test certificates are available on request. Certificate of Test of Finished Tube is provided for the tube dispatched under ASTM A249/ A269.

Related Search

Find more related products in following catalogs on Hisupplier.com