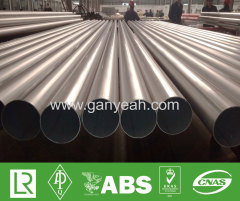

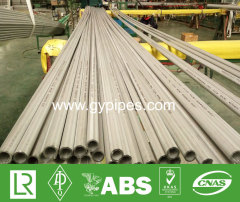

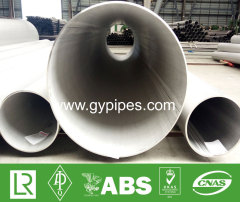

DIN SS Welded/Erw Pipe

| Price: | 3600.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Impact Test subject to Standard request

Grain Size Test and Intergranular Corrosion Test

Ultrasoic measuring of Wall Thickness

ASTM A554 SS Welded/Erw Mechanical Tube Mill Specifications:

Mill 1 – ½ ", ⅝", ¾", 1″ X1″ Square

Mill 2 – ⅞", 1″

Mill 3 – 1 ¼", 1 ½"

Mill 4 – 1 ⅝, 1.9″, 2″

80% of the sizes of the SS Tube market

Can produce 430, 409, 439, 304, 316 Tubling

Shapes ½" – 2″ rounds and 1″ Square

Finishes – Mill Finish Polished to 120, 180, 220, 320, 400 and 600 Buff

Can cut to preferred lengths

Custom made sizes and finishes

TP304 and 304L SS Welded/Erw Mechanical Tube

Type 304 Stainless Steel is the most widely used of the austenitic (chromium/nickel) stainless steels. In the annealed condition it is essentially non-magnetic and becomes slightly magnetic with the application of cold work. Type 304L Stainless Steel is preferred in welding applications to exclude the formation of chromium carbides during cooling in the heat affected region of the weld. These alloys represent an excellent combination of corrosion resistance and fabricability.

316 and 316L SS Welded/Erw Mechanical Tube

Type 316 Stainless Steel is an austenitic chromium nickel stainless steel containing molybdenum. This addition increases general corrosion resistance, improves resistance to pitting from chloride ion solutions, and provides increased strength at elevated temperatures. Properties are similar to those of Type 304 except that this alloy is somewhat stronger at elevated temperatures. Corrosion resistance is improved, particularly against sulfuric, hydrochloric, acetic, formic and tartaric acids; acid sulfates and alkaline chlorides. Type 316L Stainless Steel is an extra-low carbon version of Type 316 that minimizes harmful carbide precipitation in the heat affected zone during welding.

321 SS Welded/Erw Mechanical Tube

Type 321 Stainless Steel is a stabilized austenitic stainless steel similar to Type 304 but with a titanium addition of at least five times the carbon content. This titanium addition reduces or prevents carbide precipitation during welding and in 800 – 1500F service. It also improves the elevated temperature properties of the alloy. Type 321 provides excellent resistance to oxidation and corrosion and possesses good creep strength. It is used primarily in applications involving continuous and intermittent service temperatures within the carbide precipitation range of 800 – 1500F.

Related Search

Find more related products in following catalogs on Hisupplier.com