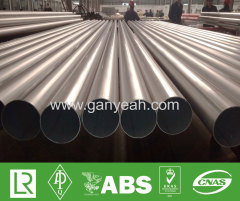

SUS347 Stainless Steel Polishing Pipes

| Price: | 4800.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The minimum tensile strength for stainless steel pipes is 515 N/mm² while minimum yield strength at Rp 0.2% at 205 N/mm².

One of the most supplied in GANYEAH GROUP's product range is stainless steel pipes. Stainless steel pipes are consumed in high performance fluid or gas line application. Most clients requests for welded stainless steel pipes due to their corrosion resistance and ability to withstand pressure.

Introduction:

GANYEAH GROUP keep stock for welded stainless steel pipes in dual grade SS316/SS316L. The stainless steel pipes are in accordance to ASTM A312. ASTM A312 is the standard specification for welded and heavily cold worked austenitic stainless steel pipe.

Stainless Steel Pipe Attributes:

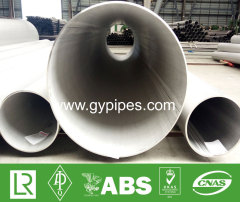

The minimum tensile strength for stainless steel pipes is 515 N/mm² while minimum yield strength at Rp 0.2% at 205 N/mm². Stainless steel pipes contain at least 10.5% of chromium. This allows it to form an invisible chrome-oxide layer by reaction with oxygen.

SS316/316L is a chromium-nickel-molybdenum bearing austenitic stainless steel. The molybdenum content in stainless steel pipe is around 2.0% to 3.0%, while nickel content is around 11% to 14%. The nickel and molybdenum content provides great corrosion resistance in corrosive surroundings, such as salt water or chloride environments. In addition, SS316/316L material will reduce the tendency of the material to crack after welding. It also provides higher tensile strength at elevated temperature.

The meaning of "L" designation in SS316L grade is that carbon content is restricted to 0.03% where the normal carbon content in stainless steel SS316 is 0.08%. The lesser the carbon content the stainless steel has, the greater it is in weldability. And it also prevents chromium from being depleted, thus, it can still form the chrome oxide layer on the pipe surface.

• 1. Commodity: Welded stainless steel pipe/tube

• 2. Process method: Cold drawn/cold rolled

• 3. Surface finish: Anneal/pickling/manual polish/mechanical polish

• 4. Material: TP304, TP304H, TP304LN, TP304L, TP310/S,

• TP316L, TP316H, TP316/316L, TP317L, TP321/321H, TP347,

• S31803 and so on.

• 5. Standards: ASTM A312/213/269, DIN17457, EN10216 , etc.

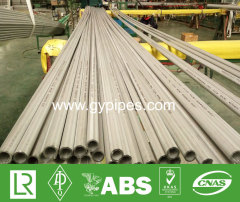

• 6. Size:

• A) NPS: 1/8" to 10"

• B) Schedule: 5/5S, 10/10S, 20/20S, 40/40S, 80/80S,

• 120/120S, 160/160S, acc. To ANSI B36.19/36.10

• C) O. D.: 6 mm to 2032 mm

• D) W. T.: 0.8 mm to 48 mm

• 7. Length: Max. 20 meters

• 8. Delivery conditions: Annealled, Picklinged and Polished

• 9. packing: Seaworthy wooden cases/steel framed cases/

• simple packaging

• 10. Certificate: ISO 9001:2000,

Related Search

Find more related products in following catalogs on Hisupplier.com