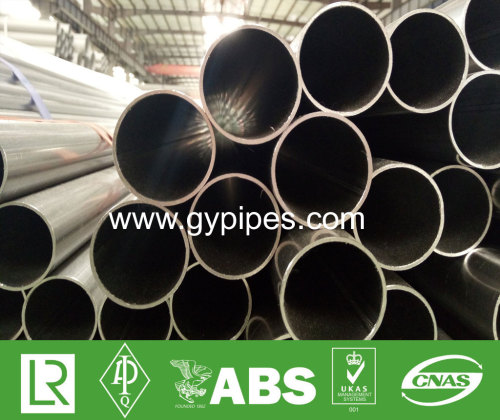

TP316/TP316L Dual Grade Welded Pipes

| Price: | 4800.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Mechanical Properties of the tubes at room temperature:

Tensile Strength Rm: Minimum 515 N/mm²

Upper Yield Point Reh: Minimum 205 N/mm²

TP316/TP316L Dual Grade Seam Pipes

Having difficulties looking for stainless steel pipes? We can help you because we have all sizes. |

To further understand more about stainless steel pipes, please see the information provided below:

Stainless Steel Pipes | Description: |

Features:

Inch NB Size Range: 1/8" to 4"

Thickness Range: SCH10S - SCHXXS

Dimension Standard: ASTM A312 / ASME SA312

Material: TP316 / TP316L

Working Pressure: As per DIN 2413 I Static Straight Pipe Specifications

Origin:China

Finishing: Annealed and Pickled

- Recommended Bend Radius:

- A bend radius of 3x the external tube diameter, is recommended for the tube's cold bending using tube benders or by manual hand bending.

- Welding Suitability:

- Pipes made of TP316 and TP316L are suitable for arc welding using usual techniques. The welding should be selected in accordance with DIN EN 1600 and DIN EN 12072 part 1 taking into account the type of application and the welding technique.

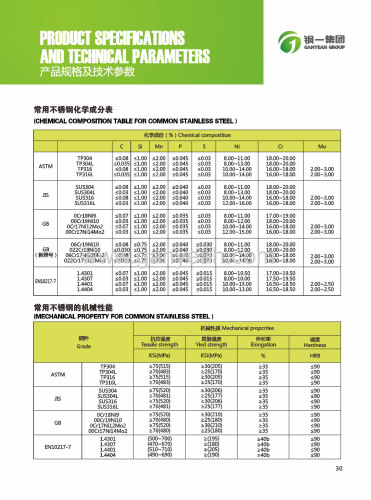

- Chemical Composition:

- Chemical composition for ASTM A312/ASME SA312, TP316/TP316L Dual Grade Seam Pipes is as per the table below.

C | Mn | P | S | Si | Ni | Cr | Mo | |

Min. | 11.0 | 16.0 | 2.00 | |||||

Max. | 0.035 | 2.000 | 0.045 | 0.030 | 1.000 | 14.0 | 18.0 | 3.00 |

Mechanical Properties of the tubes at room temperature:

Tensile Strength Rm: Minimum 515 N/mm²

Upper Yield Point Reh: Minimum 205 N/mm²

Elongation at rupture A5: Minimum 35%

Hardness Test: 75 HRB

Related Search

Find more related products in following catalogs on Hisupplier.com