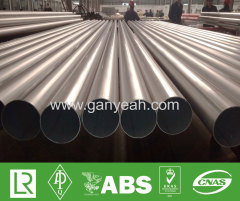

1.5 Stainless Steel Tubing

| Price: | 4500.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Company has perfect quality assurance system, advanced testing equipment and high-qualified management team with control over series of activities

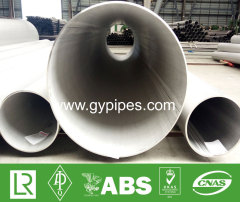

Ganyeah is committed to providing our customers with professional friendly service and maintains one of the industry's most extensive stainless steel tubing inventories including, seamless tubing and welded tubing, available in large outside diameters and small outside diameters, thin wall and heavy wall.

Ready Inventory to Meet Exacting Specifications

Our 1.5 Stainless Steel Tubing Small Diameter is manufactured in hydraulic, pressure, mechanical and boiler tube sizes. We carry stainless steel tubing in wide variety of specifications to meet your commercial, defense and aircraft requirements, AMS, ASTM, ASME, MIL-T and MIL-S specifications including full certification and mill test reports to address all your quality concerns.

If you have a hard to find, recurring, size, grade or specification in 1.5 Stainless Steel Tubing Small Diameter and are looking for a partner to help meet your budget and delivery requirements, talk to your sales representative today to see how we can help.

Welded Stainless Steel Tube

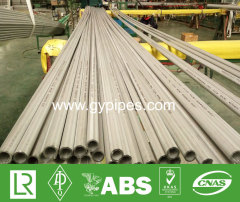

| TYPES: | 304, 304H, 304L, 309, 310, 316, 317L, 321, 321H, 347, 347H, 410, 440C, 446, 2205 Duplex |

| SPECIFICATIONS: | ASTM A213,ASME SA213,ASTM A249,ASME SA249,ASTM, A268,ASTM A269,ASTM A511,AMS 5566,AMS 5570,AMS 5571,AMS 5576, AMS 5639,AMS 5645, MIL-T-6845,MIL-T-8504, MIL-T-8808 |

Stainless Steel Tube & Pipe Specifications :

SPEC. NO. | TITLE | SCOPE | ||

ASTM A 249 | Welded Austenitic Stainless Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes. | Pressure tubes, made from austenitic stainless steels, (Types 304, 304H, 304L, 305, 309, 310,316, 316H, 316L, 317, 321, 321H, 347, 347H, 348, 348H, and XM grades.) | ||

ASTM A 268 | Seamless and Welded Ferritic Stain-less Steel Tubing for General Service. | 15 grades of ferritic stainless steel tubing for general corrosion resistance and high temperature service. (Types 329, 405, 409, 410, 429, 430, 430Ti, 443, 446, XMs & others). | ||

ASTM A 269 | Seamless and Welded Austenitic Stainless Steel Tubing for General Service. | 13 grades of austenitic stainless,steel tubing for general corrosion- resisting and high-temperature service. (Types 304, 304L, 316, 316L, 317, 321,347, 348 and XM grades). | ||

ASTM A 270 | Seamless and Welded Austenitic Stainless Steel Sanitary Tubing. | Austenitic stainless steel intended for usein the diary and food industry in sizes up"to andincluding 4 in. in outside diameter. | ||

ASTM A312 | Seamless and Welded Austenitic Stainless Steel Pipe. | Austenitic stainless steel pipe intended for high temperature and general corrosive service.22 grades are covered. | ||

ASTM A 554 | Welded Stainless Steel MechanicalTubing. | Nineteen grades are covered for mechanical applications. Rounds, squares, rectangles, and special shapes are included. | ||

MIL-T-6737 (T 321) | Tubing, Steel, Corrosion and Heat Resistant (18-8 Stabilized), Welded. Annealed. | Type 321 and 347 tubing intended use in the manufacture of exhaust stacks, manifolds, blast tubes, ring collector and similar applications where a weldable corrosion and heat resisting steel is required or for use at 800º – 1500°F. | ||

MIL-T-6845 (T 304) | Tubing, Steel, Corrosion Resistant 304) Aerospace Vehicle Hydraulic ³/ Hard, Seamless, Weldsd Drawn. | Intended for use in high pressdre hydraulic and pneumatic systems in which corrosion resistant materials are required. The tubing is not suitable for use in applications assembled by weldin or brazing or exposed to temperatures higher 800°F., because of impaired resistance to corrosion, where subsequent anneal not possible. | ||

MIL-T-8504 (T 304) | Tubing, Steel, Corrosion Resistant 18-8) Annealed, Aircraft Hydraulic Seamless, Welded. | Intended for use in high pressure hydraulic and pneumatic systems in which corrosion resistant materials are required. This tubing is of lower strength and higher ductility than tubin Speci- fication MIL-T-6845. May be used to MIL-T-6845 tubing but heavier wall thicknesses must be used. Same qualifications regarding welding, brazing & temperature. | ||

MIL-T-8506 (T 304) | Tubing, Steel, Corrosion Resistant (304) Annealed. Seamless, Welded. | Intended for use in the fabrication of aircraft parts requiring a high degree of resistance to corrosion. Not to be used in high pressure hydraulic control systems. | ||

MIL-T-8606 | Tubin , steel, Corrosion Resistant 18-8 Annealed. Welded & Drawn. | Intended for use in applications which require a high degree of resistance to corrosion or to temperatures in the range of 800°F.—1500°F., or in applications which involve welding. Suitable for use In tank-automotive equipment for hydraulic and mechanical applications. | ||

MIL-T-8808 | Tubing, Steel, Corrosion Resistant (18-8 Stabilized), Aircraft Hydraulic Quality. Annealed. Seamless, Welded & Drawn. | Intended for use in high hydraulic and pneumatic systems where and heat resistance are required and in which welding or brazing may be involved during fabrication. Resists oxidation at temperatures to 1200°F., but is useful at that temperature only when stresses are low. | ||

MIL-T-8973 | Tubing, Steel, Corrosion Resistant, Aerospace Vehicle Hydraulic System. ³/ Hard. Seamless, Welded & Drawn. | Intended for use in high pressure hydraulic and pneumatic systems corrosion and heat resistance are required and in which welding or brazing may be involved during fabrication. Suitable for use in temperatures to 1200°F., when stresses are low. | ||

MIL-P•1144 | Pipe, Stainless Steel, (Corrosion Resisting). Seamless or Welded. Annealed. | Pipe is intended for high-temperature and hy- draulic or other pressure service under general corrosive conditions. | ||

Related Search

Find more related products in following catalogs on Hisupplier.com