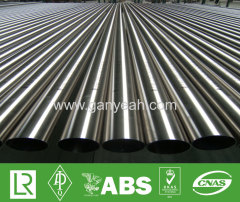

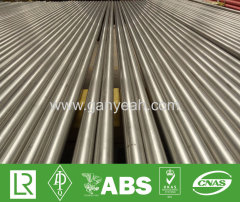

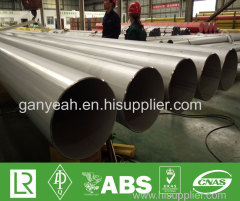

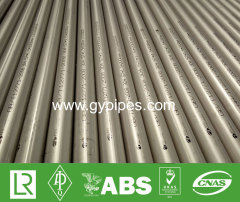

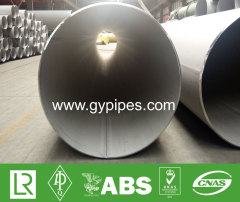

AISI 300 series stainless welding pipe

| Price: | 3200.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

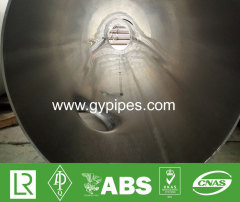

Destructive & Non-destructive Test

To assure the quality of our products, our own in-house testing facilities play an important role.

Detailed Product Description

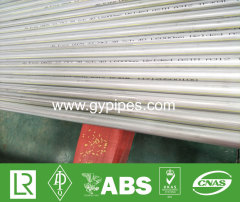

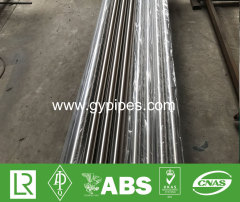

| 304 | 6mm-2020mm |

| TIG | Bright Annealed / Polished |

| ASTM A778 |

AISI 300 series stainless welded tubing SS304 Round Tube 06Cr19Ni10

ASTM A778 Specification

The ASTM A778 specification includes straight seam & spiral butt seam welded unannealed austenitic stainless steel tubular products. These are intended for low/moderate temperatures, and corrosive service where treatment is not necessary for corrosion resistance.

AISI 300 series stainless welded tubing Grades:

304,304L, 304H, 316, 316L, 316H, 321, 321H, 317, 317L, 347, 347H, 309, 309S, 310, 310S.

ASTM A778 stainless steel pipe thickness Available Sizes:

Any size can be provided but this process is usually used sizes of NPS 8'' and upper.

Eletric-Fushion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe For High-Temperature Service and General Applications

This specification cover electric-fusion-welded austenitic chromium-nickel stainless steel pipe suitable for corrosive or high-temperature service, or both, or for general applications. The pipes come in five classes.

Class1:

Pipe is double welded by processes employing filler metal in all passes and are completely radiographed.

Class2:

Pipe is double welded by processes employing filler metal in all passes without radiography

Class3:

Pipe is single welded by processes employing filler metal in all passes and are completely radiographed.

Class4:

Same as Class 3 except that the weld pass exposed to the inside pipe surface may be made without the addition of filler metal.

Class5:

Pipe is double welded by processes employing filler metal in all passes and is spot radiographed.

| EN - DIN | WNr | AISI/ Tradename | ASTM - UNS | Pipe seamless | Pipe welded | |

| X5CrNi18-10 | 1.4301 | 304 | S30400 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X6CrNiTi18-10 | 1.4541 | 321 | S32100 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X6CrNiNb18-10 | 1.4550 | 347 | S34700 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X5CrNiMo17-12-2 | 1.4401 | 316 | S31600 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X2CrNiMo17-13-2 | 1.4404 | 316L | S31603 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X2CrNiMo18-16-4 | 1.4438 | 317L | S31703 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X2CrNiMoN17-13-5 | 1.4439 | 317 LNM | S31726 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X5CrNiMo17-13 | 1.4449 | 317 | S31700 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X1NiCrMoCuN25-20-6 | 1.4529 | Alloy 926 | N08926 | B/ SB677/ A/ SA312 | B/ SB673 | |

| EN10216-5 | EN10217-7 | |||||

| X1NiCrMoCu25-20-5 | 1.4539 | 904L | N08904 | B/ SB677/ A/ SA312 | B/ SB673 | |

| EN10216-5 | EN10217-7 | |||||

| X6CrNiMoTi17-12-2 | 1.4571 | 316Ti | S31635 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

| X1CrNiMoCuN20-18-7 | 1.4574 | 254SMO® | S31254 | A/ SA312 | A/ SA358/ A/ SA312 | |

| EN10216-5 | EN10217-7 | |||||

Related Search

Find more related products in following catalogs on Hisupplier.com