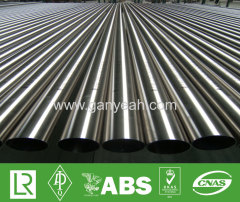

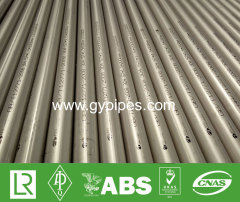

ASTM A312 TIG Welding SS Pipe

| Price: | 3500.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Using TIG Welding advantages:

A very low electrode wear.

The creation of pore-free, sound welds.

TIG welding has a very stable arc.

TIG Welding SS Pipe

Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas, or TIG Welding, is a joining process used on stainless steel. An arc welding process, TIG welding stainless steel involves the use of an non-consumable tungsten electrode in order to deliver a weld.

Most commonly used for welding thin stainless steel sections, TIG Welding SS Pipe manufacturers a greater control over the weld when compared to other welding processes such as Gas Metal Arc Welding (GMAW) and Shielded Metal Arc Welding (SMAW).

TIG welding is also the most commonly used process because of its versatility, the high quality weld it delivers as well as the aesthetically pleasing appearance of the finished weld. The ability of the process to weld at low currents (hence a lower temperature input) and to add filler wire when required, makes it an ideal process for both thin materials as well as for root runs in the one sided welding of thicker plate and pipe sections.

TIG Welding SS Pipe can be done with or without the use of filler wire (known as autogenous welding) and is thus the chosen process for the orbital welding of fixed pipe.

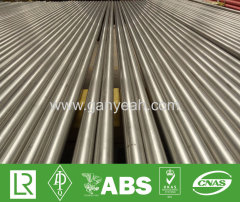

The most popular shielding gas used in TIG welding stainless steel pipe and other sections, is pure Argon, but Argon rich mixtures with additional helium, hydrogen or nitrogen is also used to achieve specific results.

Inert backing gas protection of the weld under bead is used when single sided welding is performed. This protection is employed in order to prevent oxidation as well as the loss of the stainless steel's resistance to corrosion.

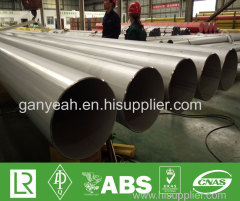

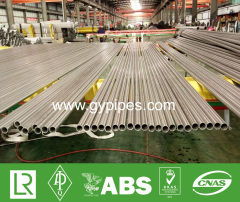

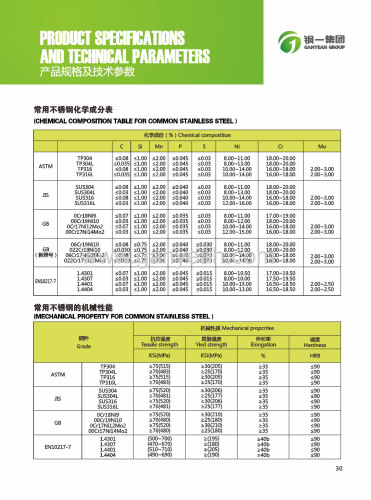

Austenitic Grades

This group of stainless steels contain:

17% - 25% Chromium

8% - 20% Nickel

As well as a number of additional elements that help manufacturers achieve the required properties.

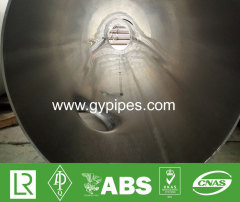

T304

Delivering the best all-round performance, this stainless steel grade is one of the most versatile and most widely used. With a lower carbon Carbon content, this grade shows a slightly higher resistance to corrosion that T302.

Following welding, it has a lesser susceptibility to inter-granular corrosion.

T304L

A low carbon stainless steel, this grade has a resistance to corrosion that is similar to that of T304. It does however have a superior inter-granular corrosion resistance after welding stress-relieving processes. This grade is recommended for use in parts which have been fabricated through welding processes and, as a result, cannot be annealed.

Products made using this grade are limited to a service temperature of a maximum of 426°C.

T310S

Specifically developed for high temperature services (a maximum of ± 1 100°C) in which high creep strengths are a requirements, this grade is however not recommended in long service situations as brittleness may occur.

This grade is also non-magnetic when annealed as well as when cold worked.

Related Search

Find more related products in following catalogs on Hisupplier.com