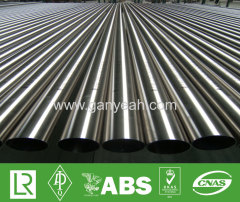

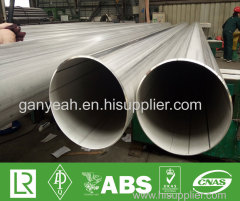

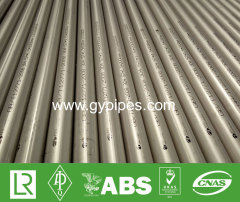

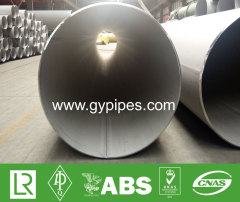

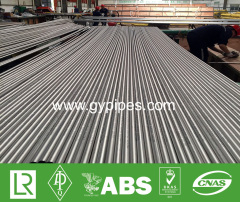

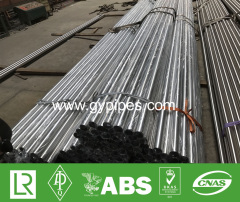

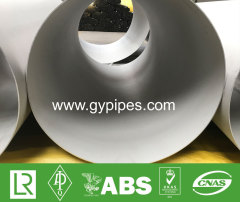

Stainless Steel Pipe Schedule 10

| Price: | 3500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The manufacturing welded process pipes require that the customers' needs regarding the safe conveyance of corrosive, flammable and toxic fluids

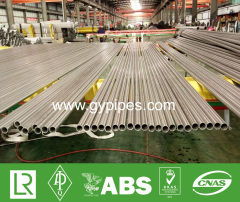

Plant fabrication and field installation of industrial piping systems is a key area of competency for GANYEAH.A broad range of Welding Procedure Specifications, a well tooled pipe shop and a highly skilled workforce allow us to confidently deliver on projects of this type.

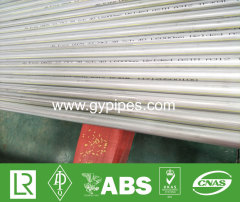

Licensed to fabricate and install Welded Stainless Steel Pipe Schedule 10 in compliance with ASME B31.1, ASME B31.3, and CSA B51

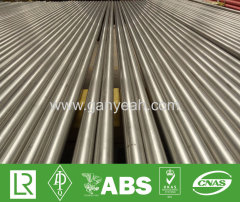

Pipe fabrication involving carbon and alloy steels, including stainless, chrome-moly, titanium, inconels, monels, and duplex

Instrument based dimensional control

Heat Treatment

Bolt Tensioning & Torquing

Hydrotesting

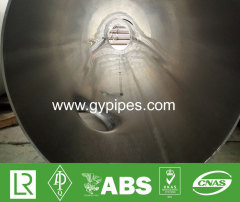

Process Welded Stainless Steel Pipe Schedule 10 are primarily used in the pulp & paper, chemical and petrochemical industries. Pipes in chemical tankers, and for handling of water such as in pipelines, sewage and desalination plants, are yet other important applications.

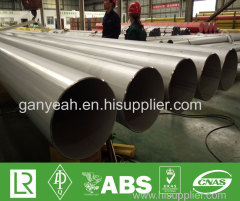

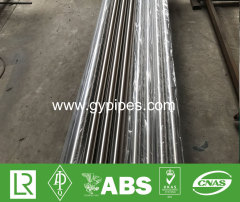

The manufacturing, distribution and sales of welded stainless steel process pipes require

that the customers' needs regarding the safe conveyance of corrosive, flammable and toxic fluids and gases must be fulfilled.GANYEAH offers from our extensive stock programme more than 600 different articles for all types of applications within the process industries.

In our Product Catalogue you can find more detailed information on for example product standards, tolerances, our stainless steel grades and material selection and design.

| Bore | OD | WT | Weight KG per metre |

| 15 | 18 | 1.5 | 0.619 |

| 20 | 23 | 1.5 | 0.806 |

| 25 | 28 | 1.5 | 0.994 |

| 32 | 35 | 1.5 | 1.26 |

| 40 | 43 | 1.5 | 1.56 |

| 50 | 53 54 | 1.5 2 | 1.93 2.60 |

| 65 | 68 69 | 1.5 2 | 2.49 3.35 |

| 80 | 83 84 | 1.5 2 | 3.06 4.10 |

| 100 | 103 104 | 1.5 2 | 3.81 5.10 |

| 125 | 128 129 | 1.5 2 | 4.75 6.35 |

| 150 | 153 154 156 | 1.5 2 3 | 5.68 7.60 11.50 |

| 200 | 203 204 206 | 1.5 2 3 | 7.56 10.10 15.20 |

| Bore | OD | WT | Weight KG per metre |

| 250 | 254 256 | 2 | 12.60 19.00 |

| 300 | 304 305 306 | 2 2.5 3 | 15.10 18.90 22.70 |

| 350 | 355 356 | 2.5 3 | 22.00 26.50 |

| 400 | 406 408 | 3 4 | 34.00 40.40 |

| 450 | 456 458 | 3 4 | 34.00 45.40 |

| 500 | 506 508 | 3 4 | 37.70 50.40 |

| 600 | 606 608 | 3 4 | 45.20 60.40 |

| 700 | 706 708 | 3 4 | 52.70 70.40 |

| 800 | 806 808 | 3 4 | 60.20 80.40 |

| 900 | 908 910 | 4 5 | 90.40 80.40 |

Related Search

Find more related products in following catalogs on Hisupplier.com