EFW Steel And Tube Stainless

| Price: | 3500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

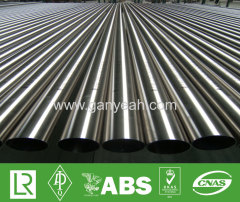

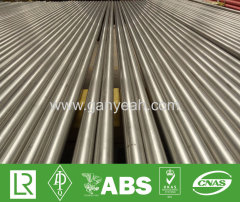

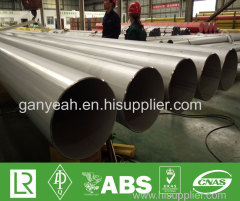

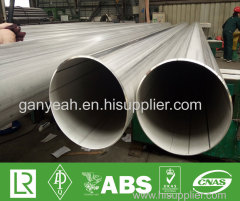

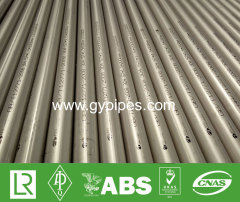

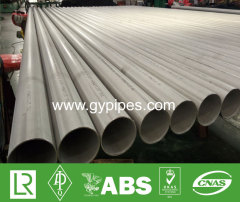

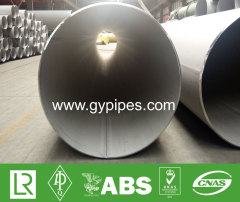

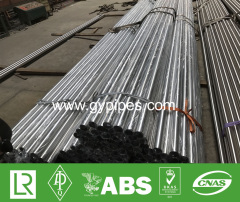

Welded Pipe:

Finish: Annealed & pickled, bright annealing, polished

Ends: Beveled or plain end, square cut, burr free ,Plastic Cap at Both end

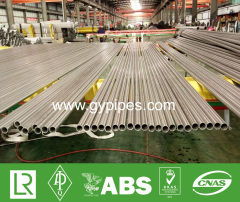

Welded Steel And Tube Stainless Specification :

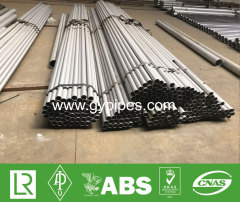

Specifications : ASTM, ASME, DIN, NFA, JIS

Dimensions : ASTM A312/ A358 / A409 / A790, ASTM A530, ASTM A106, ASTM A 333, ASTM A240.

ASTM A213, A53, ASTM A 333, ASTM A335, A387, ASTM A928

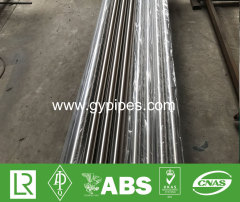

Thickness : 11mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

0.4mm to 8mm

Pipes Size : 1/8" NB to 36" NB

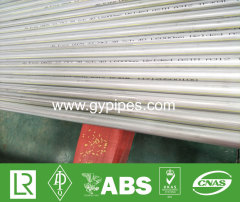

Tubes Size : 1/8" OD to 8" OD

Length : Cut length, Fix length, 100mm to 12mtr long.

Form : Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, "U" Shape, Pan Cake Coils, Hydraulic Tubes

End : Plain End, Beveled End, Treaded

Type : Welded

Welded Steel And Tube Stainless Material & Grades :

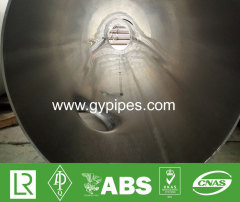

Stainless Steel Welded Pipes & Tubes : ASTM A312/ A358 / A409 / A790 TP series - 201, 304, 304H, 304L, 304N, 304LN, 309, 310, 310S, 316, 316H, 316L, 316LN, 316Ti, 317, 317L, 321, 321H, 347, 347H, 904L. UNS series - S31803, S32750, S32760, NO8904.

ASTM A213 TP series - 201, 304, 304H, 304L, 304N, 304LN, 309, 310, 310S, 316, 316H, 316L, 316LN, 316Ti, 317, 317L, 321, 321H, 347, 347H, 904L. UNS series - S31803, S32750, S32760, NO8904.

Duplex & Super Duplex Steel Welded Pipes & Tubes : ASTM A240 / ASME SA240 UNS NO. S31803 , S32205 , S32550 , S32750 , S32760.

ASTM A928 / A928M UNS NO. S31803 , S32205 , S32550 , S32750 , S32760

Typical applications of the various stainless steel types

| TypesTypical | Applications |

| 420 (martensitic) | Cooks and professional knives, spatulas etc |

| 430 (ferritic) | Table surfaces, equipment cladding, panel (ie components requiring little formability or weldability). Used for moderately corrosive environments (e.g. vegetables, fruits, drinks, dry foods, etc). |

| 304 (austenitic) | Vats, bowls, pipework, machinery parts (i.e. components requiring some formability or weldability). Corrosion resistance superior to 430. |

| 316 (austenitic) | Components used with more corrosive foods (e.g. meat/blood, foods with moderate salt contents), which are frequently cleaned, with no stationary solids and not under excessive stress. |

| 1.4539 (austenitic) | Used with corrosive foods (e.g. hot brine with solids that act as crevice forms, stagnant and slow moving salty foods). |

| 1.4462 (duplex) | Used with corrosive foods (e.g. hot brine with solids, stagnant and slow moving salty foods). Higher strength than austenitics. Good resistance to stress corrosion cracking in salt solutions at elevated temperatures. |

| 6%Mo. types (austenitic) | Used with corrosive foods (e.g. hot brine with solids, which act as crevice formers, stagnant and slow moving salty foods). Good resistance to stress corrosion cracking in salt solutions at elevated temperatures. Used in steam heating and hot work circuits, hot water boilers, etc |

Related Search

Find more related products in following catalogs on Hisupplier.com