You are here: home > Industrial Stainless Steel Pipe > Stainless steel pipe for LNG industrial

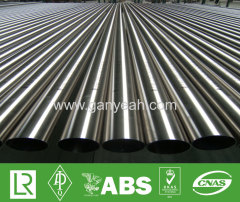

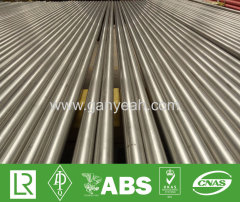

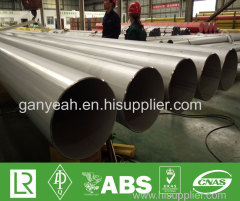

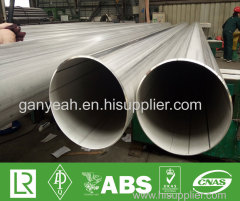

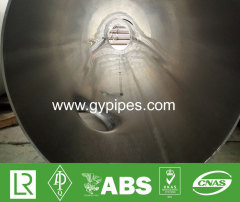

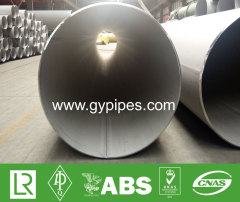

Stainless steel pipe for LNG industrial

| Price: | 3500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

730640

Production Capacity:

2000Ton/Month

Delivery Date:

15days

Grade:

SUS 304/304L/ 316L/347H/S32...

Inspection:

UT, ET, HT, RT

Certification:

API 5LC,DNV•GL, ABS, TUV, L...

Surface:

Pickling,annealing,polishin...

Origin:

China

Means of Transport:

Ocean,Land

Packing:

Plastic, Wooden Case, Other...

Brand:

Ganyeah

Standard:

Astm a312/Astm a778/Astm a5...

Section Shape:

Round

Length:

6 m or as customers' reques...

HS Code:

730640000/730611000

Technical engineer from oil company and third party inspection company

One-stop service for steel industry for pipeline project application

Specifications for Manufacturing ASTM A312 stainless steel pipe for LNG industrial:

Stainless 304/304L | With 18 percent chromium and 8 percent nickel, 304 is the most common stainless steel grade. 304L is the low carbon version of 304. All tubular products are readily available in 304 and 304L stainless steel |

Stainless 304H | Like standard 304, this grade is also an 18 percent chromium and 8 percent nickel stainless steel. This grade requires a minimum carbon content of .04. The higher carbon content gives 304H greater heat resistant qualities, higher yield strength, and better short term and long term creep strength. Longer lead times could be required to deliver 304H in some tubular forms. |

Stainless 316/316L | This grade has more nickel than 304 and 304L and includes molybdenum. 316 and 316L have superior corrosion resistance to 304 and 304L in most instances. 316 and 316L stainless steel is readily available in all product forms. |

Stainless 317/317L | 317 and 317L contain more molybdenum and has overall better corrosion resistance resistance than 304, 304L, 316, and 316L stainless steels. 317L offers higher resistance to chloride pitting compared 304L and 316L. 317 and 317L is available in seamless pipe. Other tubular products can be provided, but a larger lead time could be required. |

Stainless 309 | 309 stainless steel has good strength and resistance to oxidation at high temperatures. This grade has better overall corrosion resistance than 304 stainless steel. |

Stainless 309S | 309S has lower carbon content than regular 309 and is recommended for applications where sensitization and subsequent corrosion by high temperature gases or condensates during shutdown may pose a problem. In some cases, tubular products may be dual certified to 309 and 309S. |

Stainless 310 | This grade combines excellent high temperature properties with good ductility. 310 stainless is designed for high temperature service applications. In most applications, 310 stainless resists oxidation at high temperatures. |

Stainless 310S | Stainless grade 310S calls for lower carbon content than standard 310 stainless. In many cases, 310 and 310S are dual certified. See full data sheet for comparison. |

Stainless 310H | Stainless steel grade 310H has higher carbon content and is often selected for high temperature applications. 310H is used in environments that produce sulfur dioxide gas at high temperatures. |

Stainless 321 | 321 Stainless Steel is an austenitic chromium-nickel stainless steel that contains titanium. This is best for use in welded parts that cannot be annealed. |

Stainless 321H | 321H grade stainless steel is the higher carbon version of grade 321. It possesses enhanced creep resistance and higher strength at temperatures above 10,000F (537°C). Usually, the plate's carbon content allows dual certification. |

Stainless 347 | 347 Stainless Steel is a stabilized austenitic stainless steel similar to type 304, but it also contains columbium and tantalum. |

Stainless 347H | 347H Stainless Steel is a columbium-stabilized austenitic stainless steel plate. It has good general corrosion resistance, as well as slightly better resistance in strong oxidizing conditions than grade 321. |

| SPECIFICATION | APPLICABLE TO |

| A / SA 213 | For Seamless Tubes mainly applicable to Heat Exchangers, Super Heater & Steel Boilers |

| A / SA 249 | For Welded Tubes mainly applicable to Heat Exchangers, Boilers, Condenser, Super Heater, etc. |

| A / SA 268 | For Seamless & Welded Tubes for General Services |

| A / SA 269 | For Seamless & Welded Tubes for General Services |

| A / SA 312 | For Seamless & Welded Pipes |

| A / SA 358 | For Welded Pipes |

| A / SA 688 | For Welded Water Heater & Heat Exchangers U-Tubes |

| A / SA 789 | For Seamless & Welded Duplex Stainless Steel Tubes, Pipes & U-Tubes. |

| DIN 17456 | For Seamless Tubes For General Services. |

| DIN 17457 | For Welded Tubes For Specific OR Special Requirements. |

| DIN 10216-5 | For Seamless Tubes For Specific OR Special Requirements. |

| DIN 10217-5 | For Welded Tubes For Specific OR Special Requirements. |

| NF A 49-117 | For Seamless Ferritic & Austenitic Stainless Steel Tubes for General Services. |

| NF A 49-217 | For Seamless Ferritic, Austenitic Stainless Steel Tubes For Heat Exchangers. |

| JIS G 3459 | For Stainless Steel Pipes. |

| JIS G 3463 | For Stainless Steel Boiler & Heat Exchanger Tubes. |

Application of Stainless Steel Round Tube:

1. Chemical Industries

2. Petrochemical Industries

3. Refineries Plants

4. Fertilizers

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Stainless Steel Pipe

Stainless Steel Pipe Fittings

Stainless Seamless Steel Pipe

Seamless Stainless Steel Pipe

Stainless Steel Seamless Pipe

Welded Stainless Steel Pipe

More>>

Find more related products in following catalogs on Hisupplier.com