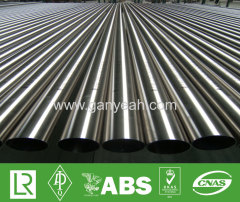

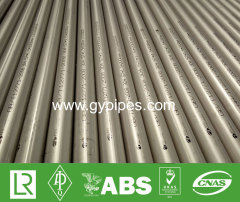

Electro Polishing Stainless Steel Pipe

| Price: | 3800.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Electropolishing superior than mechanical polishing :

A. a surface potential conditions;

B. difficult to capture pollutants;

Procedure: Electro Polishing Industrial Stainless Steel Pipe and Mechanical Polishing Stainless Steel Pipe.

Definition:

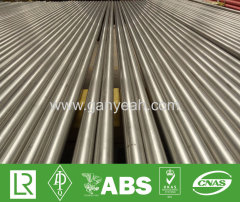

Electro Polishing Industrial Stainless Steel Pipe process is actually the inside or outside surface of the pipe polishing process, using polishing equipment and the friction of pipes surface, to meet the roughness requirement.

Type:Stainless steel tube of polishing with internal surface polishing and external polishing.

Polishing grade: the outer surface of #400, #600, brushed, Silk hair.

Application: Mechanical treatment, Mechanical working, CNG, Automobileengine.

Electropolishing features: Electro polishing is the use of stainless steel in the electrolyte solution in the selectivity of the anode to achieve the purpose of polishing and cleaning the surface of a surface treatment.

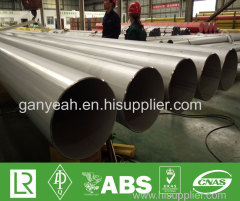

Electro Polishing Industrial Stainless Steel Pipe Advantages:

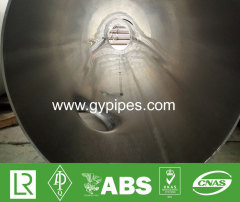

(1) Greatly improved corrosion resistance. Since electropolishing selective dissolution of the elements , making a solid surface of chromium-rich layer of dense solid transparent membrane , and formation of electric surface , eliminating and reducing micro- cell corrosion .

(2) Micro- electrolytic polishead surface is more smooth than the mechanical polishing , reflecting a higher rate . This makes the device non-stick wall , not hanging material , easy to clean surface about a reduction of approximately one wire , to GMP and FDA regulatory requirements .

(3)Electrolytic polishing from the workpiece size and shape restrictions. Mechanical polishing on the appropriate implementation of the workpiece can be polished , for example, thin tube wall , elbow , bolts , nuts and containers inside and outside the wall .

| Pipes according to ASTM A312 | ||||||||

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo |

| TP 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | |

| TP 304L | 0.035 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-13.0 | |

| TP 316L | 0.035 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| Note: For small diameter or thin walls or both, where many drawing passes are required, a Carbon maximum of 0.040% is necessary in grades TP 304L and TP 316L. Small outside diameter tubes are defined as those less than 0.50 in. [12.7 mm] in outside diameter and light wall tubes as those less than 0.049 in. [1.20 mm] in average wall thickness (0.044 in. [1.10 mm] in minimum wall thickness). | ||||||||

Related Search

Find more related products in following catalogs on Hisupplier.com