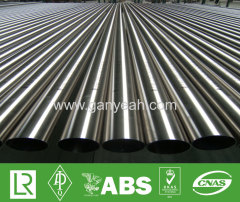

Erw Inox Perforated Steel Tube

| Price: | 3500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Fabricating Corrosion Resisting and Stainless Steel-corrosion resistance,storage,handling,forming and cutting, welding, fabrication, and passivating.

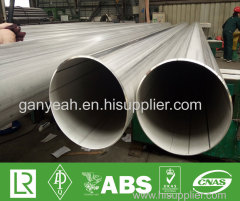

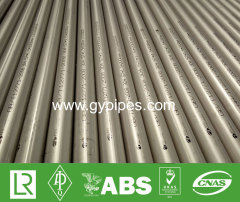

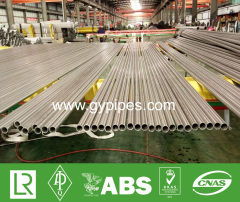

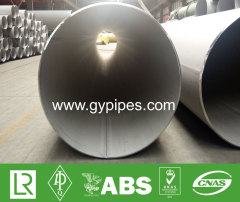

Welded Inox Perforated Steel Tube

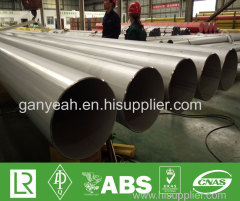

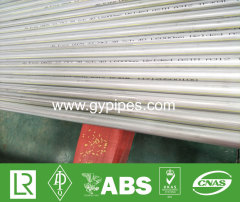

1.Standard : According to ASTM /ASME /SA312 , ASTM /ASME A213/SA213, ASTM /ASME /SA269, ASTM A249 , ASTM A279, DIN 17456-85, DIN17458-85, JISG3459, JISG3463, JISG3448, JISG3446 ETC

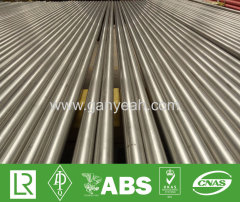

2. Material: TP304,TP304L,TP304/304L,TP304H,TP304LN,TP321,TP316,TP316L, TP316/316L, TP316Ti, TP321, TP310,TP310S,TP317L,TP347,TP347H etc.

3. Outside diameter: 8~2000mm. Wall thickness 0.5~60mm

4. Length: 1-20m random or fixed.such as 6m fixed,5-7m random etc.

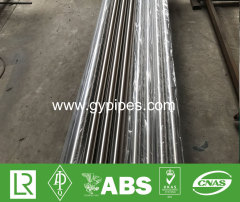

5. Process Method: TIG welding,ERW welding,PAW welding,Online solution annealing.

6. Polishing: 600#,400#, 320#, 240#, 180#.etc.

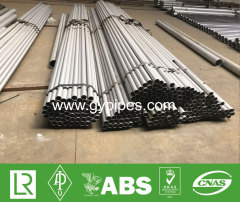

7. Used for petroleum chemical, metallurgy, paper making, food, shipbuilding, environmental protection, boiler, heat exchanger , pressure container, condensator, water, electricity and so on.

8. Quality guarantee: Tubes non-destructive testing, eddy current test, ultrasonic detector, spectrum analyzer,rockwell hardness testing, tension test, metallographic microscope etc.

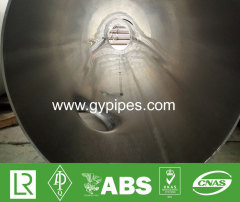

9. Details Including: liquid transportation pipes; gas transportation pipes;boiler tubes;structure pipes; hygeian tube. protection, boiler, heater exchanger, pressure container, condensator, water, decorative pipe,electric ,etc.

Introduction to Stainless Steel - austenitic, ferritic, duplex, martensitic, and precipitation hardening stainless steels.

Stainless Steel vs Corrosion: How stainless steel is affected by and resists corrosion - corrosion process, passivity, general corrosion, galvanic corrosion, erosion/abrasion, intergranular corrosion, pitting corrosion, crevice corrosion, and stress corrosion cracking.

Mechanical Properties of Stainless Steel - mechanical properties, austenitic, ferritic, martensitic, duplex, and precipitation hardening stainless steels.

Surface Finish on Stainless Steels - design, finish and fabrication, mill forms, fabrication and special finishing methods, pickling and passivation, cleaning stainless steel, care on site and erection, and routine cleaning and maintenance.

Fabricating Corrosion Resisting and Stainless Steels - corrosion resistance, storage, handling, forming and cutting, welding, fabrication, and passivating.

Cutting of Stainless Steels - mechanical cutting, thermal cutting, and new technology.

Metallurgy of Stainless Steels - history, classifications, and characteristics of stainless steels.

Welding and Joining of Stainless Steels - nature of stainless steel, weldability, processes, shielding gases, dissimilar metals, and fume control.

Machining Stainless Steels - tooling, cutting fluids, corrosion resistance, drilling, turning, tapping, die threading, thread rolling, reaming, and milling.

Practical Considerations for Designing in Stainless Steel - resistance to environment, mechanical properties, fabrication, economic considerations.

Stainless Steel and Stainless Alloy Castings - processes, classifications, chemical composition, microstrucure, heat treatment, machining, welding, mechanical properties, and applications of stainless steel castings.

Forging Stainless Steels - production of forging, starting stock for forging, heating for forging, cooling after forging, and post forging requirements.

Stainless Steel Pipe and Tube - production manufacturing processes, welding processes, finishing operations, longitudinally welded vs seamless, forming, and applications.

Cold Forming Stainless Steels - stainless steel formability and forming processes.

Deep Drawing of Stainless Steels - properties and practical considerations for deep forming processes.

Stainless Steel and Stainless Alloys at High Temperature - mechanical properties and corrosion resistance.

Ferritic Stainless Steels - properties, performance, availability and considerations for fabrication.

Related Search

Find more related products in following catalogs on Hisupplier.com