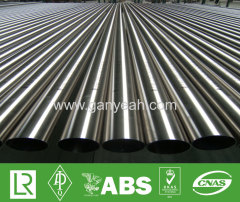

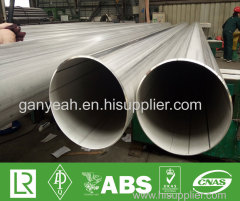

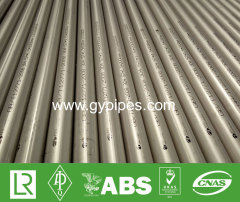

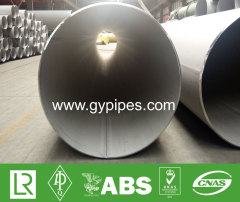

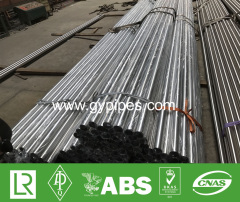

Erw 304 Stainless Steel Pipe Specifications

| Price: | 3500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

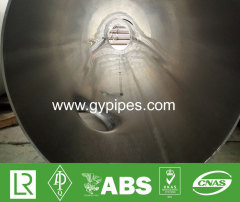

The offered range of welded pipe is made utilizing high grade raw material and innovative techniques in strict compliance with the quality norms

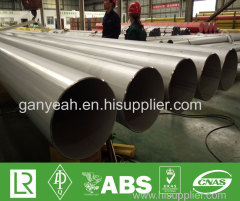

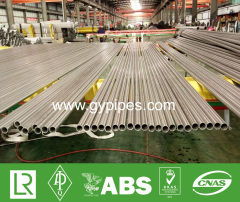

GANYEAH GROUP started its manufacturing unit a decade ago for STAINLESS STEEL ERW PIPES & TUBES with production range from 1/4" NB to 60"NB manufactured on continues fully automated tube mills of TIG welding without any addition of filler metal (A 312) & are in close contact with the manufacturer having the manufacturing facility from 10" NB to 24" NB with the addition of filler wire.(A 358).

304 Stainless Steel Pipe Specifications

| Material | TP 304, 304H, 304L, 304LN, 316, 316H, 316L, 316LN, 316Ti, 309, 310, 317L, 321, 347, 409, 410, 420, 430, 446 Etc. |

| Standard | ASTM A - 270, 249, 312, 269, 213, 268, 358 |

| Construction | ERW - EFW - EFSW |

| Schedule | S 5, S 10, S 20, S 40, S 60, S XS, S 80, S 100, S 120, S 140, S 160, S XXS |

| Pipe Type | Beweld End (BW), Plain End Pipe (PE) |

304 Stainless Steel Pipe Specifications Technical Data

S.S Schedule Piping to ASTM A-312 (ERW)

Introduction & Scope

This covers straight seam welded (without the addition of filler metal) authentic stainless steel pipe intended for high temperature and general corrosive service.

Material

Material is ordered to comply with the requirement of ASTM A-240 in 304, 304L, 316 and 316L grades regularly. Special grades can be made as per Customer's requirements.

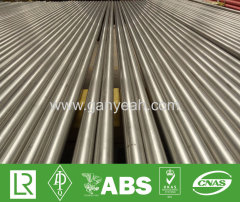

Size Range

OD : ½" NPS (21.3 mm) to 8" NPS (219.1 mm)

Thick : NB size in schedule 5 10 S & 40S

Length : As per Customers Requirement.

Process of Manufactures

The pipe is manufactured from annealed strips on modern continuous forming mills with TIG welding process under inert gas atmosphere. All pipes are annealed at a minimum temperature of 1050°C, straightened, pickled and passivated, end finished & 100% tested in accordance with ASTM A-530

Tolerances

| OD | Size Range | Over mm | Under mm |

| Upto 1" NB | 0.40 | 0.79 | |

| Over 1" NB to 4" NB | 0.79 | 0.79 | |

| Over 4" NB to 8" NB | 1.57 | 0.79 | |

| Thickness : ± 12.5 of nominal wall thickness | Length : 0/+ 6 mm | ||

Test

Normal : Tensile strength / Yield strength / Elongation, Flattening, Hydrostatic Pressure

Optional : Pneumatic / Air leakage, Eddy current, IG Corrosion

Standard Weight Chart

| Outside Dia | SCH 5 | SCH 10 S | SCH 40 S | ||||

| NB Inch | mm | ||||||

| Thick | Kg/Mtr. | Thick | Kg/Mtr. | Thick | Kg/Mtr. | ||

| ½" | 21.3 | 1.65 | 0.81 | 2.11 | 1.01 | 2.77 | 1.29 |

| ¾" | 26.7 | 1.65 | 1.03 | 2.11 | 1.30 | 2.87 | 1.71 |

| 1" | 33.4 | 1.65 | 1.31 | 2.77 | 2.12 | 3.38 | 2.54 |

| 1 ¼" | 42.2 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 1 ½" | 48.3 | 1.65 | 1.93 | 2.77 | 3.15 | 3.68 | 4.11 |

| 2" | 60.3 | 1.65 | 2.42 | 2.77 | 3.98 | 0.481 | 0.531 |

| 1" | 25.40 | 2.11 | 3.74 | 3.05 | 5.34 | 5.16 | 8.76 |

| 3" | 88.9 | 2.11 | 4.58 | 3.05 | 6.54 | 5.49 | 11.45 |

| 3 ½" | 101.6 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 4" | 114.3 | 2.11 | 5.25 | 3.05 | 7.52 | 5.74 | 13.77 |

| 5" | 141.3 | 2.77 | 9.50 | 3.40 | 11.74 | 6.55 | 22.10 |

| 6" | 168.3 | 2.77 | 11.47 | 3.40 | 14.04 | 7.11 | 28.68 |

| 8" | 219.1 | 2.77 | 14.99 | 3.76 | 20.25 | 8.18 | 43.16 |

Related Search

Find more related products in following catalogs on Hisupplier.com