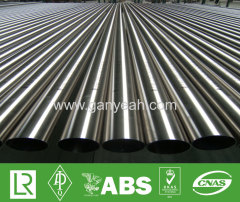

Highest Grade Of Stainless Steel Erw Pipe

| Price: | 3500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

straight seam welded (without the addition of filler metal) authentic stainless steel pipe intended for high temperature service, or both.

Highest Grade Of Stainless Steel Pipe Technical Data

S.S Fusion Welded Pipe from Plates as per ASTM A -358

Introduction & Scope

This covers electric - fusion welded authentic Chromium-nickel stainless steel pipe suitable for corrosive or high temperature service, or both. Five classes of pipe are covered under this specification.

Introduction & Scope

Class 1 : Double side welded using filler Material and 100% radiography

Class 2: Double side welded using filler Material. No radiography required

Class 3 : Single side welded using filler Material and 100% radiographed.

Class 4: As class 3, Accept root pass may be made without filler

Class 5: Double welded using filler Material and spot radiographed

Highest Grade Of Stainless Steel Pipe Material

This specification covers nineteen grades of Material steel. The plate material comply with there requirements of ASTM A-240. Most commonly manufactured grades are 304, 304L, 304H, 316L 310

Highest Grade Of Stainless Steel Pipe Size Range

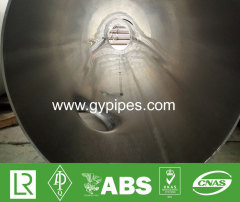

OD : 10" NPS (273.05 mm) to 24" NPS (609.6 mm)

Thick : NB Size in Schedule 5, 10S, 10 and 40 S

Length : As per customer specification

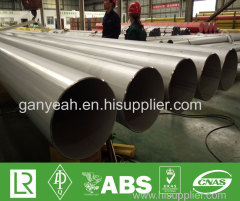

Process of Manufactures

The pipes are manufactured from leveled plates which are edge beveled and progressively "O" formed on hydraulic presses. The edges of he pipe are either manually TIG welded or continuously welded on Track and Boom. Weld portion is radiographed as per requirement. Annealing of pipe is carried our on continuous furnace. Pipe is further straightened, sized, end finished, pressure tested, pickled and passivated, marked and packed.

Tolerances

OD : + ± 0.5% of specified diameter based on circumferential measurement.

Thick : Minimum thickness at any point not more than 0.3 mm under nominal thi

Out of Roundness : difference between maximum and minimum OD 1%

Straightness : 3 mm in 3 mtrs

Length : As per customer specification

Test

Transverse bend weld tests

Transverse tension test to ASME code IX para QW 150.

Hydrostatic Test ASTM A-530

Radiographic classed 1,3 to ASMIE Code VII para UW 51, Class 5 to ASME Sec. VII para UW 52

| Outside Dia | SCH 5 | SCH 10 S | SCH 40 | ||||

| NB Inch | mm | ||||||

| Thick | Kg/Mtr. | Thick | Kg/Mtr. | Thick | Kg/Mtr. | ||

| 8" | 219.08 | 277 | 14.99 | 3.76 | 20.250 | 8.18 | 43.16 |

| 10" | 273.05 | 3.40 | 22.97 | 4.19 | 28.200 | 9.27 | 61.20 |

| 12" | 323.85 | 3.96 | 31.72 | 4.57 | 36.530 | 9.53 | 74.92 |

| 14" | 355.60 | 3.96 | 34.87 | 4.78 | 41.973 | 9.53 | 82.55 |

| 16" | 406.40 | 4.19 | 42.18 | 4.78 | 48.051 | 9.53 | 94.66 |

| 18" | 457.20 | 4.19 | 47.15 | 4.78 | 54.129 | 9.53 | 106.78 |

| 20" | 508.00 | 4.77 | 60.13 | 5.54 | 69.674 | 9.53 | 118.90 |

Stainless Steel Pipes Mechanical Properties

| Grade | Tensile Strength min. Ks(Mpa) | Yield Point Ksi (Mpa) | Elongation % (G.L.: 2 in ro 50 mm | Hardness Text Max | ||||

| Full Section specimen | Strip Specimen t<6/16in t<5/16in | Round Specimen | Brinell | Rockwell | ||||

| 304 | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 304L | 70(485) | 25(170) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 304 H | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 316 | 75(515) | 30(305) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 316L | 70(485) | 25(170) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 316H | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 316 Ti | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 317 | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 309 | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 310S | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 310H | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 321 | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 321 H | 75(205) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 347 | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

| 347H | 75(515) | 30(205) | 35 | 35 | 56t+17.50 | 28 | 192 | B 90 |

Related Search

Find more related products in following catalogs on Hisupplier.com