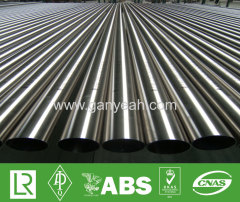

Stainless Steel Pipe Erw

| Price: | 4500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

We can help supply all of the ASTM A312 Stainless Steel Pipes, A312 Seamless/Welded Pipes for use in the oil or natural gas industries.

SUS316L Stainless Steel Pipe Erw are fabricated in different alloys of ASTM / ASME SA 312 GR. TP 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316L, 316H , 316Ti , 317 , 317L , 321 , 321H , 347 , 347 H , 904L ASTM / ASME SA 358 CL 1 & CL 3 GR . 304 , 304L , 304H, 309S ,309H , 310S, 316 , 316H , 321 , 321H , 347 and others. Our comprehensive range includes welded stainless steel pipes, ERW alloy steel pipes, welded steel pipes and many more. We produce using ace quality of steel and alloy to retain their durability for longer period.

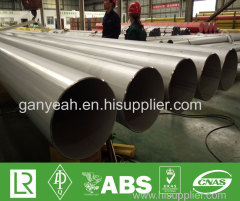

STAINLESS STEEL ERW / WELDED PIPES AND TUBES RANGE :

15 NB UP TO 600 NB IN SCH 5S , 10S ,10, 20 , 40S , 40 , STD , 60 , 80S , 80 , XS , 100 , 120 , 140 , 160 & XXS

STAINLESS STEEL ERW / WELDED PIPES AND TUBES TYPE

ERW / WELDED

STAINLESS STEEL ERW / WELDED PIPES AND TUBES FORM

ROUND, SQUARE, RECTANGULAR, HYDRAULIC ETC.

STAINLESS STEEL ERW / WELDED PIPES AND TUBES LENGTH

SINGLE RANDOM, DOUBLE RANDOM & CUT LENGTH

STAINLESS STEEL ERW / WELDED PIPES AND TUBES END

PLAIN END, BEVELLED END, TREADED

SUS316L Stainless Steel Pipe Erw / WELDED PIPES AND TUBES VALUE ADDED SERVICES

Hot Dip Galvanizing

Electro Polish

Draw & Expansion

Nominal | Outside | Nominal Wall Thickness (mm) | ||||||||||||

A | B | SCH-5S | SCH-10S | SCH-20S | SCH-40 | Other Common Thickness | ||||||||

8 | 1/4 | 13.8 | 1.2 | 1.65 | 2.0 | 2.2 | - | - | - | - | - | - | - | - |

10 | 3/8 | 17.3 | 1.2 | 1.65 | 2.0 | 2.3 | 1.5 | 2.5 | - | - | - | - | - | - |

- | - | 20.4* | - | - | - | - | 2.0 | 2.5 | - | - | - | - | - | - |

15 | 1/2 | 21.7 | 1.65 | 2.1 | 2.5 | 2.8 | 2.0 | 3.0 | 3.2 | - | - | - | - | - |

- | - | 26.4* | - | - | - | - | 2.0 | 2.5 | - | - | - | - | - | - |

20 | 3/4 | 27.2 | 1.65 | 2.1 | 2.5 | 2.9 | 2.0 | 2.8 | 3.0 | 3.2 | - | - | - | - |

- | - | 33.4* | - | - | - | - | 2.0 | 2.5 | 3.0 | - | - | - | - | - |

25 | 1 | 34.0 | 1.65 | 2.8 | 3.0 | 3.4 | 2.0 | 2.5 | 3.2 | 3.5 | 4.0 | - | - | - |

32 | 1 1/4 | 42.7 | 1.65 | 2.8 | 3.0 | 3.6 | 1.5 | 2.0 | 2.5 | 3.2 | 3.5 | 4.0 | 4.5 | 5.0 |

40 | 1 1/2 | 48.6 | 1.65 | 2.8 | 3.0 | 3.7 | 1.5 | 2.0 | 2.5 | 3.2 | 3.5 | 4.0 | 4.5 | 5.0 |

50 | 2 | 60.5 | 1.65 | 2.8 | 3.5 | 3.9 | 1.5 | 2.0 | 2.5 | 3.0 | 3.2 | 4.0 | 4.5 | 5.0 |

65 | 2 1/2 | 76.3 | 2.1 | 3.0 | 3.5 | 5.2 | 1.65 | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 | 5.5 | - |

80 | 3 | 89.1 | 2.1 | 3.0 | 4.0 | 5.5 | 2.0 | 2.5 | 3.2 | 3.5 | 4.5 | 5.0 | 6.0 | - |

90 | 3 1/2 | 101.6 | 2.1 | 3.0 | 4.0 | 5.7 | 2.0 | 2.5 | 3.5 | 5.0 | 6.0 | - | - | - |

100 | 4 | 114.3 | 2.1 | 3.0 | 4.0 | 6.0 | 2.0 | 2.5 | 3.2 | 3.5 | 4.5 | 5.0 | 5.5 | 6.5 |

125 | 5 | 139.8 | 2.8 | 3.4 | 5.0 | 6.6 | 2.5 | 3.0 | 3.5 | 4.0 | 5.5 | 6.0 | 6.5 | - |

150 | 6 | 165.2 | 2.8 | 3.4 | 5.0 | 7.1 | 3.0 | 3.5 | 4.0 | 5.5 | 6.0 | 6.5 | 7.0 | - |

200 | 8 | 216.3 | 2.8 | 4.0 | 6.5 | 8.2 | 3.0 | 3.5 | 4.5 | 5.0 | 6.0 | 7.0 | 8.0 | - |

250 | 10 | 267.4 | 3.4 | 4.0 | 6.5 | 9.3 | 3.0 | 3.5 | 4.5 | 5.0 | 6.0 | 7.0 | 9.0 | - |

300 | 12 | 318.5 | 4.0 | 4.5 | 6.5 | 10.3 | 3.0 | 3.5 | 5.0 | 6.0 | 7.0 | 8.0 | - | - |

350 | 14 | 355.6 | - | - | - | 11.1 | 5.0 | 6.0 | 8.0 | - | - | - | - | - |

400 | 16 | 406.4 | - | - | - | 12.7 | - | - | - | - | - | - | - | - |

450 | 18 | 457.2 | - | - | - | 14.3 | - | - | - | - | - | - | - | - |

500 | 20 | 508.0 | - | - | - | 15.1 | - | - | - | - | - | - | - | - |

550 | 22 | 558.8 | - | - | - | 15.9 | - | - | - | - | - | - | - | - |

600 | 24 | 609.6 | - | - | - | 17.5 | - | - | - | - | - | - | - | - |

650 | 26 | 660.4 | - | - | - | 18.9 | - | - | - | - | - | - | - | - |

Remark | (1) Other nominal diameter and wall thickness subject to the approval of vendor and purchaser with MOQ requirement. | |||||||||||||

Related Search

Find more related products in following catalogs on Hisupplier.com