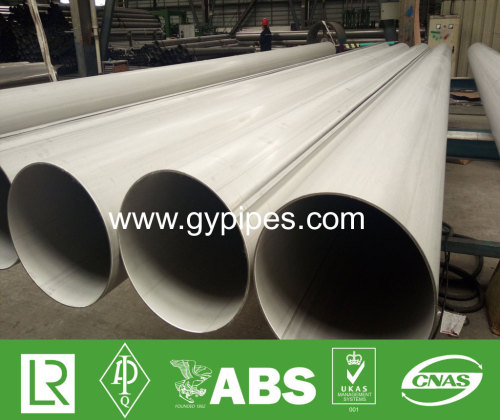

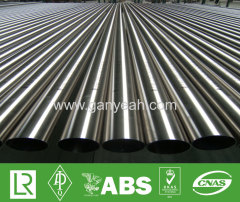

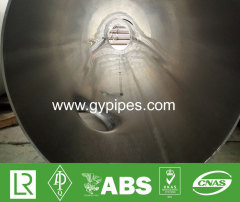

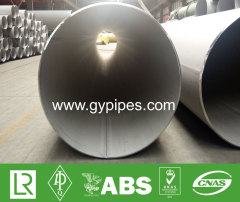

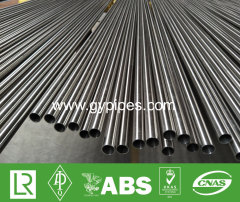

Round Stainless Steel Welding Pipes

| Price: | 3500.0 USD |

| Payment Terms: | T/T,L/C,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Our Service:

Customized Size & Surface Treatment as your requirement .

MTC is available , third Party Inspection is acceptable.

Stainless Steel Welding Pipes:

316/316L/316Ti Stainless Steel Pipe EN 1.4401 1.4404 1.4432 1.4435 1.4571 ASTM A312

316 stainless steel is a normal-carbon alternative to 316L/1.4404 that is widely used for various applications. It is an austenitic stainless steel that belongs to the standard CrNiMo stainless steel family and has normal carbon, nickel, and molybdenum content.

316L/1.4404 has low carbon content for improved resistance against intergranular corrosion after welding.

316L/1.4432 has high resistance to non-oxidizing acids and chloride-containing media due to its higher molybdenum content, and has low carbon content for improved resistance against intergranular corrosion after welding.

316L/1.4435 has low carbon content for improved resistance against intergranular corrosion after welding, increased nickel content for improved formability, and increased molybdenum content for slightly improved corrosion resistance.

316Ti is a titanium-stabilized alternative to 316L/1.4404. With its titanium content, it has enhanced resistance to welding intergranular corrosion, and can be used at elevated temperatures.

Stainless Steel Welding Pipes Standard:

ASTM A312; EN 1.4401 1.4404 1.4432 1.4435 1.4571

Elements percentage:

316

| C | Ni | Cr | Mo | Mn | N |

| <=0.08 | 10-14 | 16-18 | 2-3 | <=2 | <=0.1 |

316L/1.4404

| C | Ni | Cr | Mo | Mn | N |

| <=0.03 | 10-14 | 16-18 | 2-3 | <=2 | <=0.1 |

316L/1.4432

| C | Ni | Cr | Mo | Mn | N |

| <=0.03 | 10.5-13 | 16.5-18.5 | 2.5-3 | <=2 | <=0.1 |

316L/1.4435

| C | Ni | Cr | Mo | Mn | N |

| <=0.03 | 12.5-15 | 17-19 | 2.5-3 | <=2 | <=0.1 |

316Ti

| C | Ni | Cr | Mo | Mn | Ti | N |

| <=0.08 | 10-14 | 16-18 | 2-3 | <=2 | 0.4 | <=0.1 |

Specifications:

Seamless pipe: Φ32*3.5mm~Φ630*9mm

Straight welded pipe: DN15mm~150mm

Spiral welded pipe: DN150mm~2200mm

Any spec as per customer require

Process method:

Seamless pipe: hot rolled, cold drawing

Welded pipe: straight welding, spiral welding, ERW, LSAW, SSAW

Surface treatment:

No.1 surface

2B polish

8K mirror

wire drawing

Any spec as per customer require

Packing:

standard export packing, seaworthy packing, bundles, plastic bag, woven bag, wooden cases, plywood case, iron case, or as per customer require

Usually used steel pipe spec (GB) for reference:

Straight welded pipe:

| DN(mm) | Outer diameter Φ(mm) | Wall thickness (mm) |

| 15 | 21.25 | 2.75/3.25 |

| 20 | 26.75 | 2.75/3.5 |

| 25 | 33.3 | 3.25/4 |

| 32 | 42.25 | 3.25/4 |

| 40 | 48 | 3.5/4.25 |

| 50 | 60 | 3.5/4.5 |

| 70 | 75.5 | 3.75/4.5 |

| 80 | 88.5 | 4/4.75 |

| 100 | 114 | 4/5 |

| 125 | 140 | 4.5 |

| 150 | 165 | 4.5/5.5 |

Spiral welded pipe:

| DN(mm) | Outer diameter Φ(mm) | Wall thickness (mm) |

| 150 | 168 | 5 |

| 200 | 219 | 6/7/8 |

| 250 | 273 | 6/7/8 |

| 300 | 325 | 6/7/8 |

| 350 | 377 | 6/7/8/9/10 |

| 400 | 426 | 6/7/8/9/10 |

| 450 | 478 | 6/7/8/9/10 |

| 500 | 529 | 6/7/8/9/10 |

| 600 | 630 | 6/7/8/9/10 |

| 700 | 720 | 6/7/8/9/10/12 |

| 800 | 820 | 7/8/9/10/11/12 |

| 900 | 920 | 8/9/10/11/12 |

| 1000 | 1020 | 8/9/10/11/12 |

| 1200 | 1220 | 8/10/11/12/13 |

| 1400 | 1420 | 10/14 |

| 1600 | 1620 | 12/14 |

| 1800 | 1820 | 14 |

| 2000 | 2020 | 14 |

| 2200 | 2220 | 14 |

Related Search

Find more related products in following catalogs on Hisupplier.com