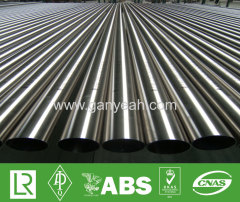

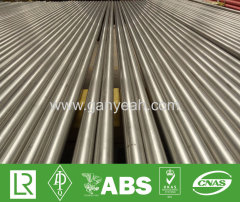

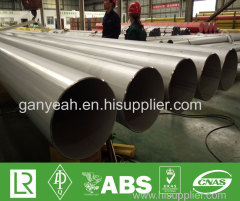

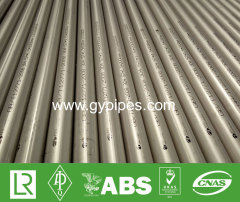

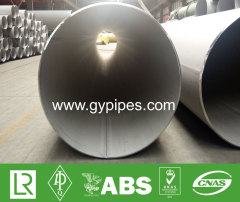

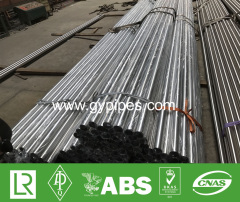

TP316L Stainless Steel Welded Pipes

| Price: | 4500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Size - Welded 304 Pipes & Tubes: 1/2" NB - 16" NB

ERW 304 Pipes & Tubes: 1/2" NB - 24" NB

EFW 304 Pipes & Tubes: 6" NB - 100" NB

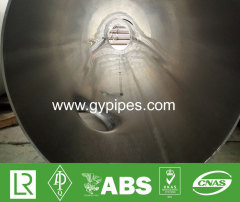

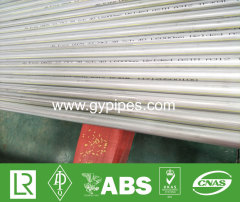

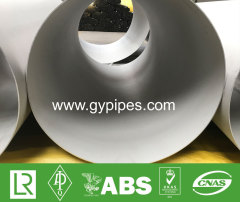

TP316L Stainless Steel Pipes

Quality remains the most remarkable factor that allows any organization to start and boom in the market. Understanding this, we have constructed a sophisticated quality testing laboratory, which is installed with the modern machinery and technology. Our quality personnel ensure to check the entire range of TP316L Stainless Steel Pipes, Fasteners, Carbon & Steel Flats and Angles and Channels thoroughly, in order to ensure its compliance with the ASTM and international standards. Different inspections such as checking the raw material (strip), testing of weld seam, surface finish, dimensions and temperature, hardness & pressure tracking are conducted on the offered range to get sure of its authenticity. These quality personnel ensure to check the entire manufacturing process, right from the procurement till the final deliverance at customers' premises.

TP316L Stainless Steel Pipes:

| Sr.No. | Process Operation | Quality Characteristics | Method of control |

| 1 | Raw Material (Strip) | 1> Dimensions 2> Chemical analysis 3> Control of Slit which within specified limits 4> Surface Actual measurement as per Std | Analysis of all elements as per Std Testing as per various Std. Measurement of width, thickness & recording visual inspection. |

| 2 | Tube Mill (GTAW Type) | 1> Weld Test, Flare Flanges, Flattering Reverse bend & Reverse Flattening 2> Inspection of weld, seam 3> Dimensions 4> Surface | Testing as per ASTM specification & recording the result. One test for every 30 to 35 Mtrs. Visual inspection weld zone. O.D. , Thickness & Length. Check roller surface profile& finish. |

| 3 | Solutions Annealing (At Min. 1040 C) With continuous water quenching. | 1> Temperature 2> Hardness 3> Micrometer | Automatic Relay Temp / Controller Adjusted to present level. Measurement of hardness as per Std. one Test / Lot / Heat |

| 4 | Straightening Straightness OD | Surface Finish | Adjust roller setting measure visual |

| 5 | Cutting | Square cut Length | Right angle to length, visual |

| 6 | Deburring | Burs removal On OD and ID Edges | Visual |

| 7 | Chemical Treatment a) Pickling b) Passivation) Bath Concentration c) Bath Concentration | Concentration Temperature | One Test / Bath Day One Test / Bath Day Temperature |

| 8 | Hydrostatic Pressure | Test Pressure | 100 % Inspection at test pressure specified as per ASTM Std. |

Related Search

Find more related products in following catalogs on Hisupplier.com