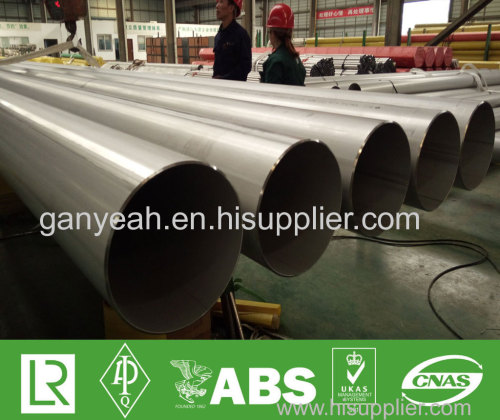

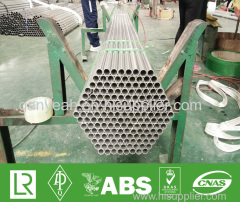

We manufacture a range of high quality Stainless Steel Welded Tubes, that are used in various industrial applications. The cold rolled stainless steel strips are welded into tubes in the state of the art tube mills under fully automated precision process. Complying with the international standards, these can be availed in various sizes and specifications to suit the diverse requirements of the clients.

The manufacturing of tubes begins with slitting of strips of required width based on the diameter of the tubes to be formed. Stainless steel slitted strips are passed through a series of rollers and SUS304 Series Stainless Steel Tubing are formed automatically on different stands with rolls and welded on fully automated process of TIG welding without the addition of filler metal.

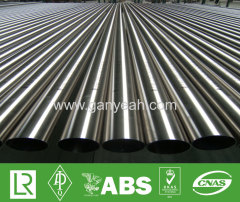

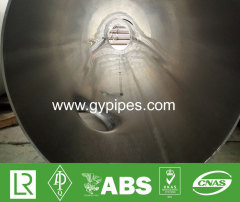

The welding head line is polished continuously with the help of automatic bead polishing machine to produce a perfect bore. The tubes are then passed through a series of sizing rolls to ensure ovality and tolerances.SUS304 Series Stainless Steel Tubing are then cut to length, cold-drawn, solution annealed, straightened, pickled, passivated and polished before other destructive and non-destructive testing & dispatch.

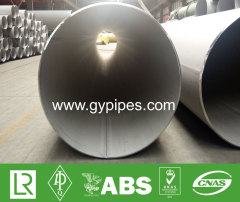

| Stainless Steel Welded / ERW Pipes and Tubes |

We offer the following : Instrumentation Tubes, Heat exchanger Tubes and General Engineering Tubes that are available in 10.00 mm to 114.30 mm OD sizes Automobile exhaust Tubes are available in 20.00 mm to 88.90 mm OD sizes range Welded Pipes are provided in 1/8" to 24" NB sizes

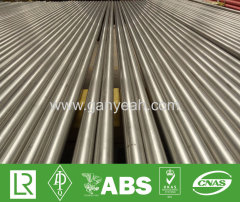

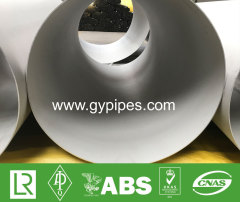

- The tubes are mainly manufactured for following industries :

Heat Exchangers Instrumentation Tubes General Engineering Automotive Industry Sugar Industry

- Size : 6.35mm to 101.6mm OD

- Thickness : 0.50mm to 4.0mm

- Specification

- ASTM A-249, A-268, A-269,

- A-270, A-554, A-688, A-778, DIN 17455 & 17457 [Class 1] & Its equivalent ASME, DIN & EN Standard.

- Grades : 304/L/H/LN, 316/L/H/LN/Ti, 317L, 321/H, 347/H, 309, 310, 904L. 409/L, 410, 430/Ti, 436, 439.

|